- The previous packhouse was outgrown.

- Automation being a must as Australia has the most expensive labour in the world.

- Automation must guarantee the same consistent quality.

- With scalability comes a growing need for control.

- Flexibility sought to respond to different market demands.

Every challenge has it’s solution.

Following are just some of the improvements that Hansen Orchards achieved:

✅ Improved throughput while maintaining consistent quality.

✅ Efficient packhouse flow with less labour dependence and optimal shelf-life allocation

✅ Full control and flexibility to maximize earnings and adapt to all customer demands

Read the full story of Hansen Orchards business transformation

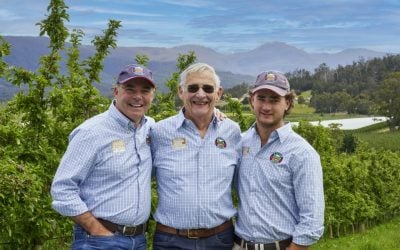

About Hansen Orchards

Hansen Orchards is a 4th generation fruit grower based in Southern Tasmania, Australia. The Hansen family first started growing, packing, and selling apples south of Hobart, in the famed `Apple Isle’, in 1890. Three generations of growers on and ensuing changes in agricultural and market practices saw competition in the sector becoming fierce to say the least. An eventual move to trial growing sweet cherries saw the family shift focus to what is now the principal product of the business today. Hansen Orchards is a vertically integrated operation, planting their own orchards as well as harvesting, grading and packing their fruit. The fruit is sold domestically as well as exported to meet market demand in 20 different countries worldwide.

Premium quality cherries as the finest gift

A substantial amount of the Tasmania based business is focused on the biggest gift giving occasion of the year in China; The Chinese New Year. Cherries destined for this discerning market are handpicked, electronically evaluated for their quality and then carefully packed. The eye catching and highly giftable 1 or 2 kg formats reach their loyal customers destined to be presents from companies to their most loyal employees and partners, a personal gift to someone special, or loved one. The cherries must be sensationally attractive, beautiful and delicious. The gift needs to be spot on, otherwise people choose other presents. There is a lot of competition in the area.

Growth potential with an operation refined to perfection

Hansen Orchards has a major competitive advantage when it comes to growing in Australia. The growing season is cooler, later, and slower than the mainland. These favorable factors help to give their large cherries a dark red colour and a smile provoking sweet taste. The operation has been refined to react to their customer needs with the end goal of delivering the highest standard of quality day in, day out. Like all growers, the primary challenge is tackled in the orchard. The year round focus on methods and care that drive the envious yields, size and packout quality.

In the packhouse, the hard work brings with it the expectation that every single cherry reaches its rightful destination in top condition, maximizing the earnings and efforts of the year’s hard work. The cherry operation boasts two grading machines of 28 lanes and up to 60 available exits. The focus is on throughput, quality, consistency and flexibility with no down time, meaning that within 48 hours of being packaged up, the cherries are delivered to the customers in Australia and Asia.

Watch the video of Hansen Orchards

Main Goals and Challenges

1. Labor efficiencies:

Australia has the most expensive workforce in the world. Full automation was the only way to be competitive in this commodity business on an international scale. Hansen Orchards needed to invest in new grading technology to improve the throughput, while maintaining their famous quality. The new grading machine had to be highly accurate and reliable to get the job done in a single shift. Double shifts are just too expensive to be competitive.

2. Moving to a new facility:

With increasing market demand and subsequent plantings outgrowing the original packhouse, Hansen Orchards were looking to build a new facility whilst optimizing the grading process with their new ideas in mind. The previous grading process was likened to a marathon race for the cherries, seeing too many changes of direction, too many high drop transfers and multiple ejection points, all of which had to be corrected.

3. Shelf-life optimization:

The shelf-life of a cherry is short. Hansen Orchards always need to pack their fruit as quickly as possible once delivered from orchard to packhouse. Stockpiling is unacceptable. Cherries must be sent directly to customers within 1 hour of being electronically sorted by the grader. It’s also crucial to sort and pack the cherries cold, because another 24 hours of cooling after packing is time wasted. If you want to handle the fruit down at these temperatures, the colder they are, the more sensitive they are to being knocked around. In such case, a grading machine with the most delicate handling is the only solution.

Choosing the right partner & technology

What were the main motivations for choosing Ellips-Elifab?

1. Fully rely on the most accurate grading technology

“We have already partnered with Ellips for over 12 years now, so we trust in their optical grading technology. We have 36 lanes of their gear in our cherry grading facility. And a couple for the apple grading facility. We have a lot of confidence in that gear. We know that Ellips is improving their technology at a quicker rate than anybody else in the world. We knew there was a new generation of high-definition cameras, new angled cameras (front and rear) and a new version of TrueSort grading software coming out. Ultimately, we need to sell absolutely every bin that arrives here, sell it like it’s our last. We must extract every last bit of value from every piece of fruit. This is made possible with the Ellips grading technology.”

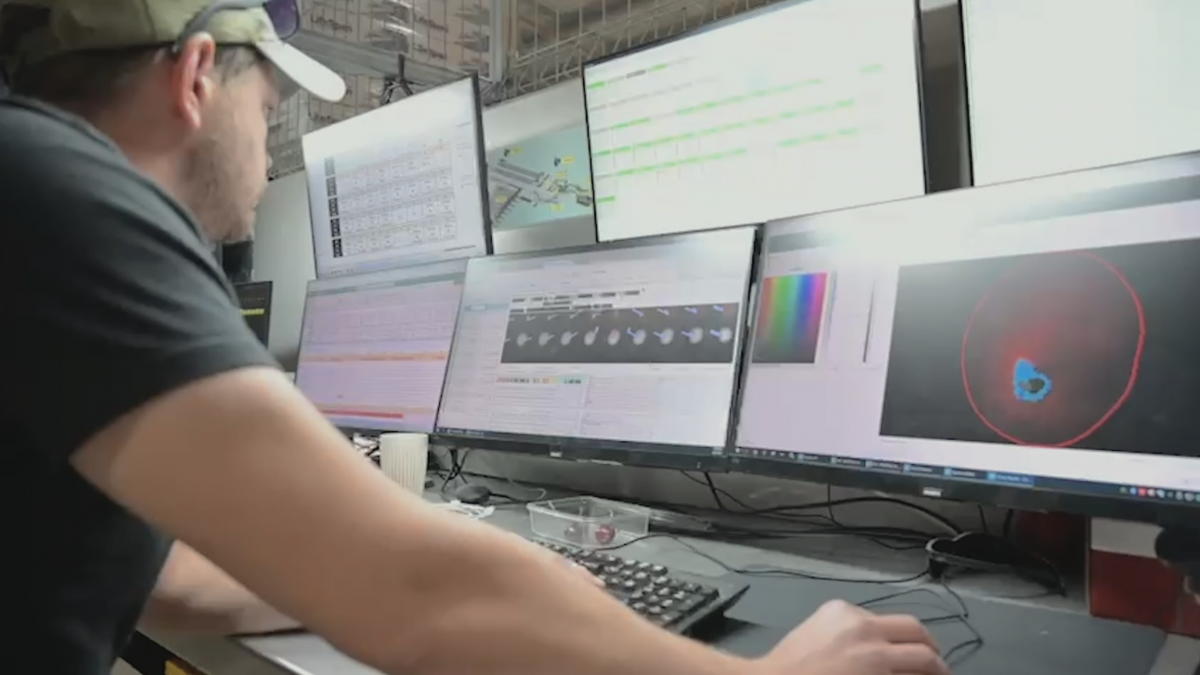

2. Operator must be in full control of the whole proces

“What we like about the Ellips technology is that the operator is in control. Too many other manufacturers are trying to basically control the machine and let the operator make minimal adjustments. With the Ellips gear, the operator is in full control. We think that’s a big advantage. We are not restricted to operate within certain parameters. With Ellips, you have the desired flexibility to respond to different market demands.”

3. Delicate machine handling and highest throughput in the market

“I still remember the first time I saw the Elifab cherry grading machine at Fruit Logistica. The yellow silicon fingers and the blue silicon covers. Every bit about this machine is about making the handling as gentle as possible. The grading machine is a real improvement. It is absolutely minimizing every drop. In addition to gentle handling, it is also the fastest grading machine in the business, allowing you to achieve maximum throughput.”

Results

“The Elifab grader is refreshingly engineered. They started on a clean sheet of paper and looked at the best way to make this machine. Easy to maintain, easy to operate and full reliability. We’ve had no major challenges with maintenance after 2 years of operating the machine. The engineering and the machine are such that it is reliable for at least 10 years. This was the biggest investment of my life. I spend my life refining the process in every detail to work in the most efficient way. We had a lot of our own ideas. Elifab embraced every one of them. Together we build the perfect machine for our situation. I think their open mindedness was another key advantage for us. We are very satisfied, because the machine is performing faultlessly.”

Following are just some of the improvements that Hansen Orchards achieved:

✅ Improved throughput while maintaining consistent quality.

✅ Efficient process with less labour dependence and optimal shelf-life allocation

✅ Full control and flexibility to maximize earnings and adapt to all customer demands

“Ultimately, every machine takes some finetuning. We did have some challenges at the start, the TrueSort software was new, the camera technology was new, the machine was new. There was improvement across several things. With the second full year, it improved on every bit and it performs faultlessly. From start to finish, the rotation is fantastic. The grading program is totally improved. We’ve still got people around the automatic box fillers, but they are there just in case. Sometimes they do double checking, but the amount of time spent on that is minimal. Because the machine is doing a really good job.”