Are you struggling to identify and sort out blueberries that that have challenging defects?

A task that is made even more difficult due to huge variations in blueberry quality across seasons, batches and varieties. Working with growers and packers around the world, we know that the world of blueberry production is challenging and fiercely competitive. Nevertheless, every day you must meet the strict market standards for quality, size, shape, color and overall appearance.

Following are the top challenges you might face, but don’t worry, we’ll also explore some solutions to ensure consistency and maximize your returns.

#1. Defects and diseases will damage your brand reputation

Because of variable weather and growing conditions, each season has different, or more prevalent, defects which makes it challenging to deliver consistent quality. Temperature changes can cause softness and decay, while humidity leads to shriveling and ofcourse rainfall is the nightmare of growers causing blueberries to crack or split. Extreme weather events, and ever stricter regulations on pesticide use, can have an even greater impact on blueberry quality. On top of that, diseases, bacteria, pests, insects and fungus can cause a range of different defects that are extremely difficult to detect.

#2 Rejection hurts your business

It only takes a small % of defective blueberries to dramatically increase the risk of rejection. More than ever, it’s important for growers to meet the ever-changing requirements and quality standards. On top of that, you must meet your volume and on-time commitments while preserving the consistency and quality of your packed product. That’s why it is critical that you do everything possible to ensure that each and every blueberry ends up in the right place.

#3. Uniformity in a world with a lot of sizes, shapes and quality differences

Every blueberry is different. So is every defect. Internal and external defects occur in many ways and can vary from season to season and batch to batch. This variability in color, size, shape and quality makes it challenging for manual graders to consistently sort blueberries into uniform grades, which can affect their marketability.

Sorting by hand is outdated, automation the industry-standard

To address the above challenges, automation of the grading and sorting process is increasingly being seen as the only way to efficiently achieve the desired quality on a consistent basis. Automation provides the added benefit of being able to maximize the value of each blueberry and to easily modify grading standards to address the unique needs of your customers. On top of all that, the reduction in labor costs can significantly impact your overall returns.

The answer to all your blueberry challenges in one: Ellips-Elifab

After a season of hard work, you want to be rewarded with maximum harvest value. Regardless of weather conditions or batch quality, you can always deliver consistent quality with the Elifab Blueberry Grading Machine (powered by Ellips grading technology). By consistently meeting your client’s quality requirements each and every season, your reputation as preferred supplier is greatly enhanced. With every blueberry graded correctly, you’ll maximize the return on each harvest while delivering exactly what your customer needs.

This is why leading blueberry growers and packers choose Elifab:

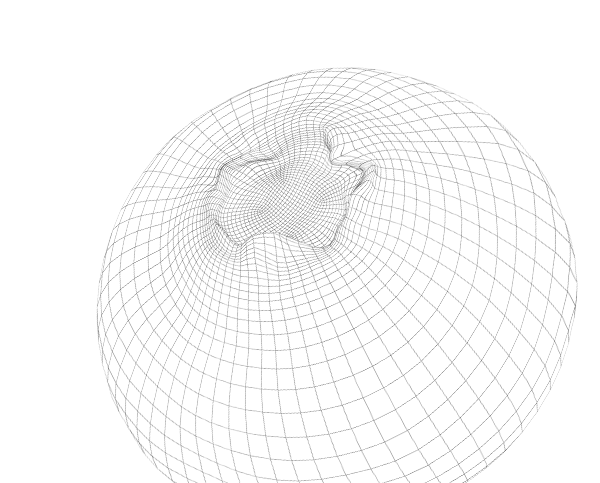

#1. 360° precision grading

Meet a blueberry grader with the best product handling and full surface inspection that handles each variation perfectly. The Elifab machine has been specially developed with a unique rotating carrier that gives you a 360° view of each blueberry. This complete analysis, achieved with 30 high-resolution images per blueberry, allows you to grade your blueberries with the highest accuracy. The Ellips TrueSort external quality system can detect every single defect at speed such as flower, slipskin, bruising, cuts, cell breakdown, compression damages, shrivel (dehydration).

#2.Delicate handling, even at top speed

Gentle handling of blueberries is crucial to avoid bruising, softening, pitting and scarring, which threaten their shelf life, appearance and market value. Fast processing shouldn’t come at the expense of fruit. It’s why Elifab uses our world-first, specially designed silicon curtains that reduce speed whilst keeping the fruit separated. Together with the lowest transfer height throughout the whole process, we have achieved the most delicate handling with little or no impact on your blueberries.

#3. True-AI. Detecting even the most difficult defects.

Artificial intelligence (AI) offers opportunities to improve your grading process with intelligent automation. With so many ways for defects to appear across every piece of blueberry, it’s only through Ellips True-AI that can accurately model all these combinations. True-AI, detects even the most challenging defects and blueberry characteristics with an eye for the smallest details. You are now able to improve detection of difficult defects like dehydration (shrivel), cracks, stem tears and mold. With grading performance moving towards 100% detection accuracy, you can fully trust the grading results and consistently deliver a superior product to your customers.

Revolutionize your blueberry business with a guarantee of consistent quality

Consistent quality is everything. With the powerful Ellips grading technology and Elifab machinery, you can detect the most challenging blueberry defects to deliver superior quality. This allows you to achieve maximum returns and the consistent quality desired by your customers. High-quality blueberries lead to improved customer satisfaction and loyalty, giving you a competitive advantage in the market.