Dealing with labor issues

Levi Bakker

Struggling to find enough skilled labor to grade and pack your harvest?

You’re not alone. For many growers and packers, labor shortages are more than just a headache—they’re a nightmare, especially during peak season. Just when you urgently need extra hands, finding and keeping skilled employees has become harder than ever.

Labor shortages don’t just create stress—they disrupt everything. Costs skyrocket, errors increase, and deadlines get tighter. You end up with higher workloads on fewer people, quality slipping through the cracks, and delays stacking up. Or worse—crops left in the field, costing you valuable revenue.

This isn’t just a headache. It’s a threat to your profitability and reputation.

What if you could reduce your dependency on labor?

Imagine a solution that tirelessly grades every piece of your produce—all while maintaining perfect quality. No missed defects. No human errors. Just consistent, high-quality results every time.

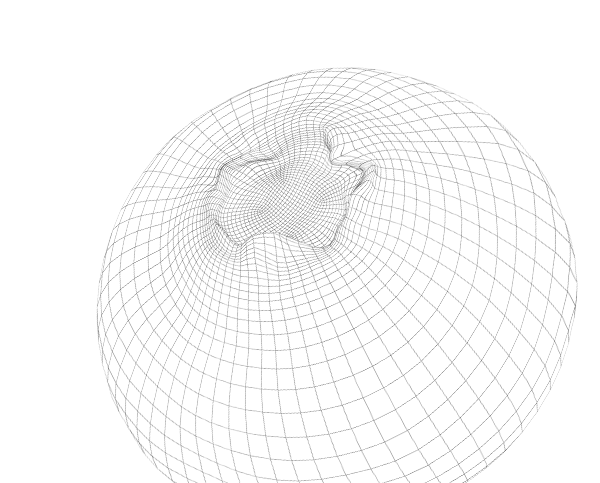

With AI-driven graders, you can fully automate the grading process at high speed. There’s minimal to no need for human post-checking. The secret? Accuracy. With advanced AI, you can trust that the system will perform better, more efficiently and more consistent than manual checks ever could.

AI doesn’t get tired or distracted. It doesn’t overlook defects at the end of a long shift. It works around the clock, ensuring every single piece meets your standard. This means you can focus on growing your business rather than managing a labor force.

What are the biggest challenges of labor issues?

- Reduced productivity:

With fewer workers available, grading and packing slow down, driving up costs and reducing efficiency. - Higher workload:

Limited staff means more pressure on fewer people to meet tight deadlines and maintain quality. - Delays:

Labor shortages lead to delayed product deliveries, affecting revenues and reliability with buyers. - Crop losses:

When there aren’t enough workers, some crops are left unharvested, resulting in significant financial losses. - Quality issues:

Without sufficient labor to carefully sort and grade crops, quality dips, impacting the marketability of your products.

The solution to labor challenges

Labor shortages are a global challenge, and the problem is only intensifying. That’s why more growers and packers are turning to automation for grading and packing. Today, AI-driven optical grading technology isn’t just an advantage—it’s a necessity for those aiming to keep up with the demands of a competitive market.

Automation only works if you can rely on it

Optical grading must be done accurate and consistent. The quality of fruits and vegetables must consistently meet high standards. This is often a top concern when exploring optical grading technology, and rightfully so—reliable results are non-negotiable. You must be able to rely on the new system. Automation only works if it is accurate, and that’s exactly what AI-driven graders deliver.

Just as good as humans? Or even better?

Growers have years of experience and knowledge, often passed down through generations. They also employ skilled individuals with a keen eye for quality. They know what to look for. But here’s what’s exciting: in demo tests and real-world use, growers are discovering that AI-driven optical grading technology is just as knowledgeable as they are. In fact, most customers are even convinced that the system has a better idea of quality than they do themselves.

Why?

Because this technology is built on the collective knowledge of growers and packers worldwide, combining generations of insight into a single system. And it goes even further. Optical grading technology can see beyond the human eye – ‘Seeing the unseen’. Such as the internal quality of products or the emergence of miniscule defects that may develop during storage or transport.

Created by growers, for growers

You can integrate your own knowledge and expertise into the system, making it as intelligent as you are. The grading software already contains various grading algorithms that can evaluate the quality of fruits and vegetables in different conditions. You have the flexibility to incorporate your own knowledge of quality aspects and defects of your produce, customizing it to your specific circumstances.

Large volumes of consistent quality elevates your status as a preferred supplier

A computer doesn’t get tired. It doesn’t lose focus or accuracy after hours of work. AI-driven grading technology maintains its precision shift after shift, allowing you to deliver large volumes with consistent quality. This builds your reputation as a trusted supplier and reinforces your status with buyers.

It’s time to rethink your grading process

Imagine delivering products that consistently meet high standards, even during peak season, without the constant worry of labor shortages. AI-driven grading isn’t just about automating a process—it’s about elevating your entire operation, giving you control over quality and efficiency no matter the labor market.

Take control of your grading and packing process today and transform labor challenges into opportunities for growth and reliability.

Ready to revolutionize your business?

Maximize throughput with less labor

Improve quality consistency

Get the most value out of each produce

Contact us or request a demo

Contact Levi

Request demo