Turn every harvest into maximum value

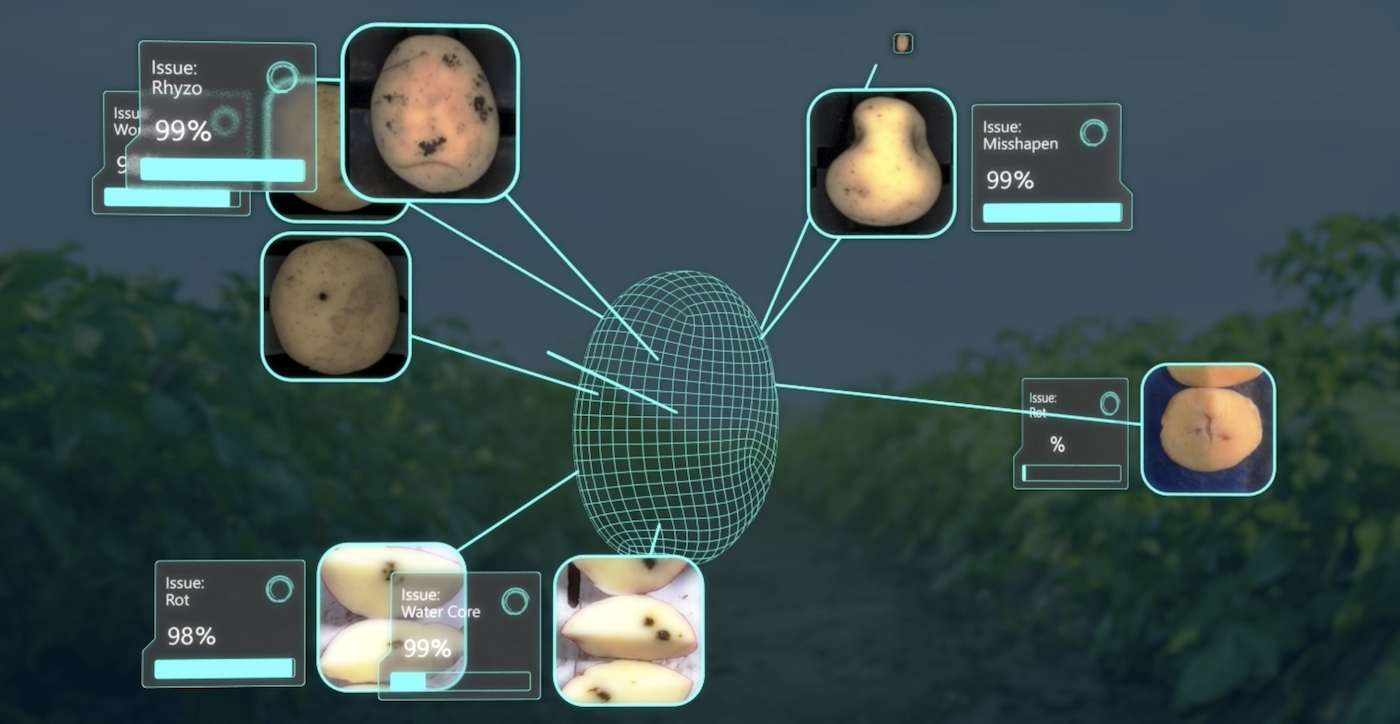

After a season of hard work, you want to be rewarded with maximum harvest value. Regardless of weather conditions or batch quality, you can always deliver consistent quality with the Elisam Potato grading machine (powered by Ellips grading technology).

What are the main powerful benefits of grading technology?

✅ Meet any demand;

✅ Powerful defect detection;

✅ Maximize throughput;

✅ Consistent quality;

✅ Less labor requirements.

Already dozens of US potato packers use the Ellips-Elisam grading machine daily.

What challenges did they face? What results have they achieved?

Discover the customer stories from Wada Farms, Folson Farms, Pioneer Potatoes and O.C. Schulz & Sons in this article.

1. Wada Farms surpasses its ROI in the very first year using optical grading technology

"This project exceeded our expectations from the initial planning phase through the final production results, including surpassing our return-on-investment objectives in the very first year. All our objectives related to capacity, efficiency, quality and cost reductions were achieved. In fact, within the first 30 days of operation, we hit our first production milestone, reaching the throughput rate (i.e., pounds per hour) that we had established for year end. The early successes boosted our confidence and enabled us to rely on the system to meet expanded production and quality goals.”

Kip Yeates - Wada Farms.

Main challenges Wada Farms:

- Enhance production efficiency considering labor and costs.

- Deliver consistently sized and graded quality products.

- Improve grading accuracy to avoid false positives and increase returns.

- Hand sorting is prone to human error and oversight.

- Mechanical sizing and manual sorting struggle with grading, handling, capacity, and market demands.

Achievements Wada Farms:

✅ Labor related to manual sizing and sorting was reduced by 75%.

✅ Improved quality consistency and operational flexibility to respond to customer demands

✅ Increased grading capacity by over 20%.

Want to discover the full story?

Explore Customer Story Wada Farms

2. This is how Folson Farms guarantees superior potato quality

“Folson Farms works to produce quality potatoes in the rich soils of the Red River Valley. Our focus is to provide customers with a consistently quality product. Ellips-Elisam stood out for its gentle potato handling, unmatched quality consistency and throughput. Our operations are now more efficient with fewer labor requirements and higher capacities."

Casey Folson – Folson Farms

Main challenges Folson Farms:

- You sometimes have difficult batches.

- The type of defects that affect potato quality vary from year to year.

- With hand grading it’s difficult to achieve the quality you want.

- Labor is hard to find.

- The throughput per hour was not sufficient to handle the potential volumes.

Achievements Folson Farms

✅ Increased quality consistency

✅ Improved production capacity to expand business potential.

✅ Created a reliable, efficient operation that is less dependent on labor.

Want to discover the full story?

Explore Customer Story Folson Farms

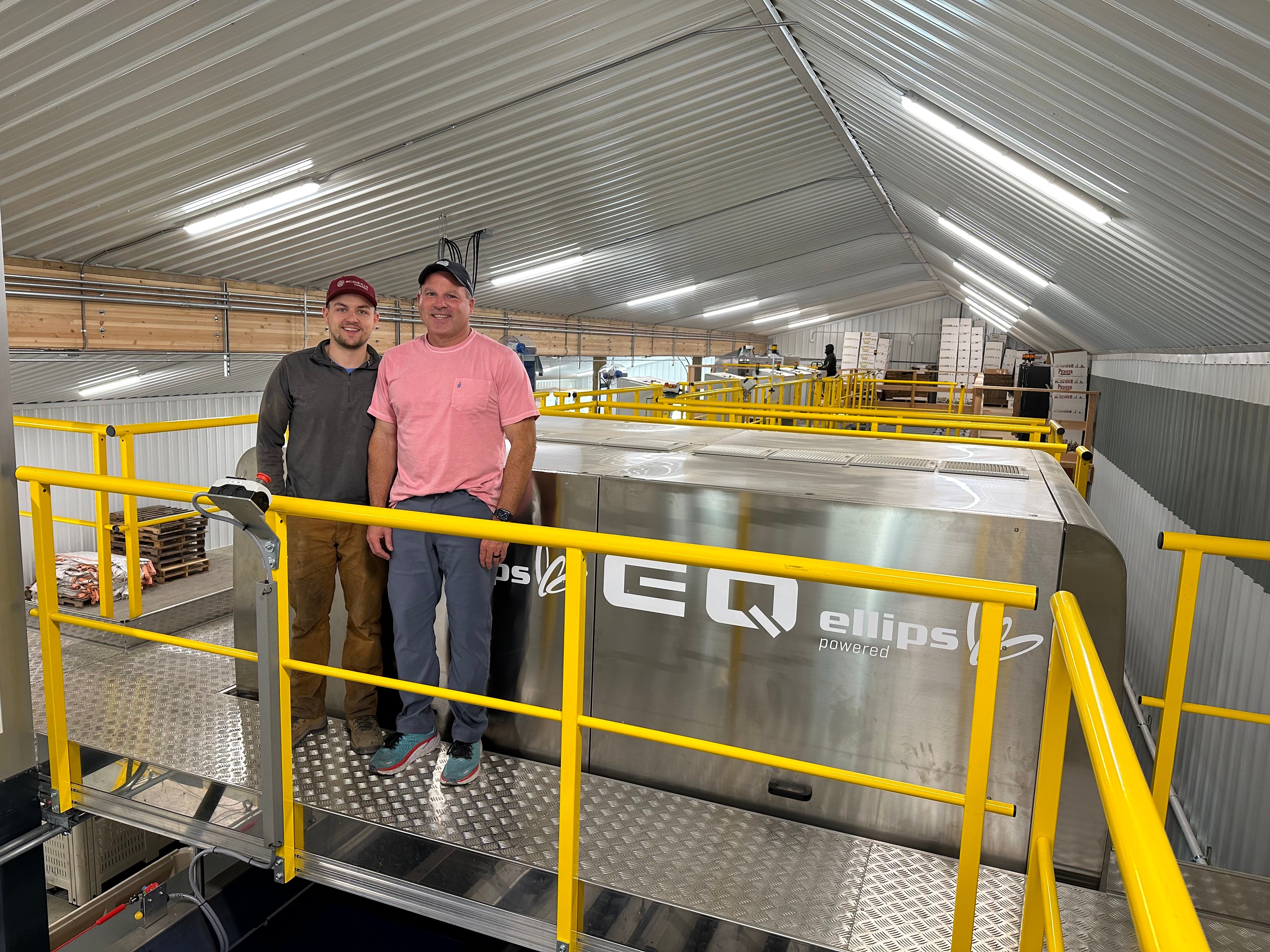

3. Smaller-scale grower Pioneer Potatoes achieves big results with grading technology

“Pioneer Potatoes understands the fundamentals of effectiveness and efficiency in grading and provisioning potatoes. Despite smaller acreage, we prioritize delivering top-quality potatoes. We maximize our harvest, producing a high percentage of A-size, premium potatoes. I am happy and proud that we, as a relatively small family farm, have been able to effectively deploy and utilize Ellips-Elisam’s potato grading and packing technology. I know that I am the customer, but I am grateful that I can use this grading technology every day."

Wylie Thulen – Pioneer Potatoes

Main challenges Pioneer Potatoes:

- Difficulty in finding and retaining workers year-round.

- Rising labor costs and competitors investing in automation.

- Manual grading can't compete with advanced grading technology.

- Inconsistent defect detection with manual sorting.

- Difficulty in quickly changing grading standards with manual processes.

Achievements Pioneer Potatoes:

✅ Monumental cost savings by reducing our workforce by 50%.

✅ Improved product quality through powerful defect detection and consistent grading.

✅ Accurate classification across all grades optimizes crop value and minimizes waste.

Want to discover the full story?

Explore Customer Story Pioneer Potatoes

4. This is how O.C. Schulz & Sons takes customer satisfaction to perfection

"The customer is always right" is our motto at O.C. Schulz & Sons. We understand the importance of customer satisfaction and strive daily to exceed expectations. We ensure consistent quality and on-time delivery. Our high-quality red and yellow potatoes are renowned for their clear skin and outstanding taste. In the past, we faced limitations in meeting all customer needs. It’s hard to put the transition in words since the installation of the Ellips solution has changed our operation so significantly. Everything is much easier now. We have a peace of mind because we can respond to any customer demand - we never have to say no anymore"

Dave and Andy Moquist - O.C. Schulz & Sons

Main challenges O.C. Schulz & Sons:

- Labor shortages occasionally disrupt operations.

- Seasonal weather variations make consistent quality delivery challenging.

- Manual sorting is inconsistent and tiresome.

- Hand sorting leads to misclassification of potatoes.

- Labor shortages and quality issues limit potato processing and packing capacity.

Achievements O.C. Schulz & Sons:

✅ Reduce dependency on labor by eliminating virtually all manual grading.

✅ Improved quality consistency to increase customer satisfaction.

✅ Increased production capacity to improve on-time deliveries and expand business opportunities.

Want to discover the full story?

Explore Customer Story O.C. Schulz & Sons

Are you looking into optical grading technology and machinery?

Your potato business is unique. It’s why every partnership we have with customers is different. With complex individual needs, business pressures, harvest characteristics and more. Our aim is to work closely with you to focus on what will work for your specific packhouse and maximize your return on investment.