Cherry quality is heavily influenced by seasonal changes. Maintaining consistency in quality becomes challenging due to Chile's recent a-typical weather conditions. An unusual amount of rainfall and insufficient hours of cold affected the fruit. This is where the timely introduction of new grading technology utilizing artificial intelligence (AI) proves to be crucial. Javier Contesse, the general manager of Allegria Foods, highlights the fundamental role of Ellips True-AI in securing the quality of exported cherries.

After rain comes sunshine in the form of Artificial Intelligence.

Contesse explained: “Given the unexpected weather conditions during the flowering, we envisioned a complex season ahead. Based on this, we informed the scenario to Elifab, who presented us with a solid proposal that led Allegria Foods to decide to incorporate the new True-AI technology. The packing process has been a real challenge. We have received lots of very different quality and with a lot of fruit affected by rotting or splitting. Having highly accurate grading technology is fundamental for a successful season.

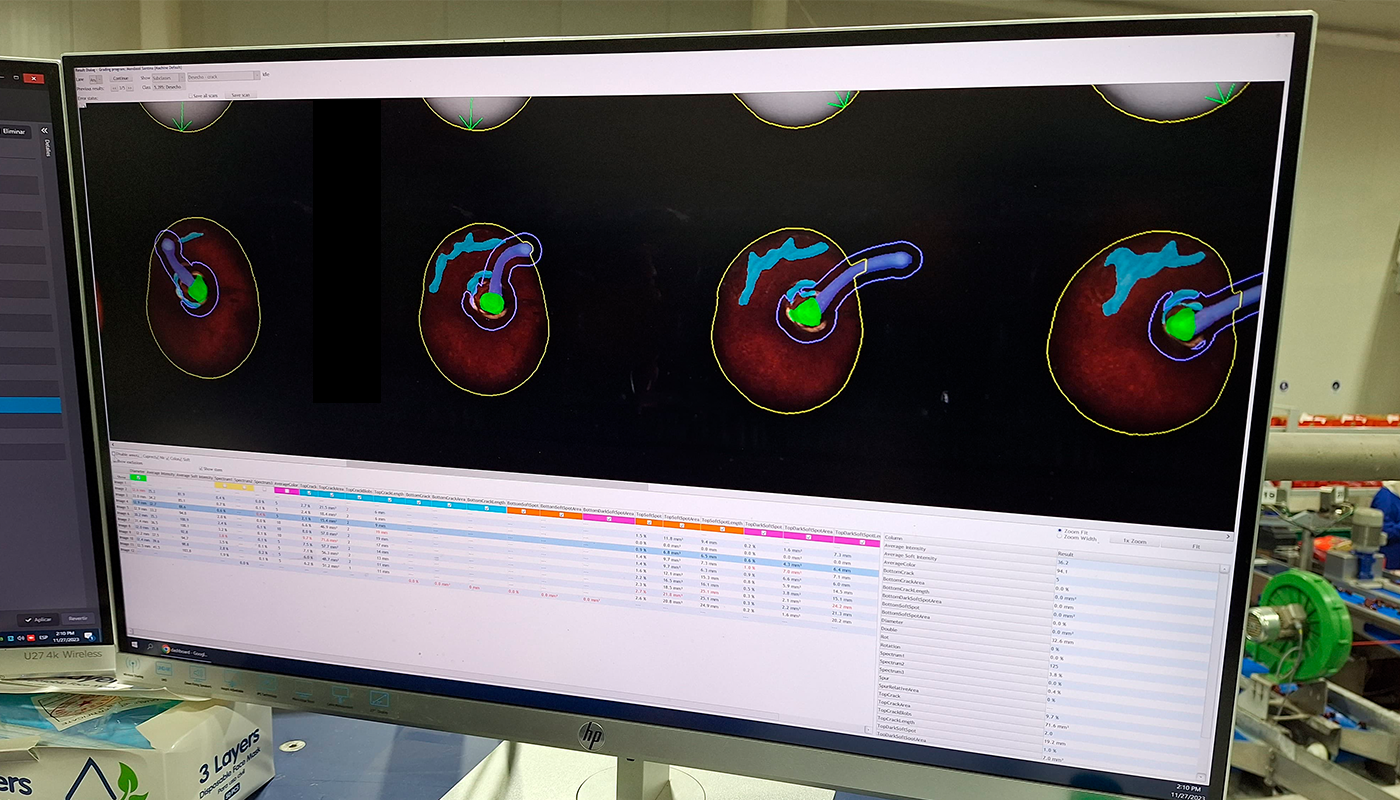

Although it is a new project, unique in Chile, what caught our attention is the machine's ability to 'refine its eye on each fruit'. It proves outstanding grading improvements of challenging defects such as black rot, fresh cracks and cracks within the stem area. It is also remarkable that with every detection, the system gains strength and improves its precision in analyzing each individual cherry. With sensational reliability in detecting stems, neighboring stems and stem attachment points it’s a real gamechanger.”

Challenging defects have nowhere to hide.

Although it is too early to analyze the results of True-AI this season, Javier comments that "this technology is the most advanced we have seen. It manages to detect things that are confusing for other systems, for example: a split fruit where the color of the wound and the background color are very similar. In other systems this is confusing, today with this new technology, it is detected and eliminated immediately".

This analysis is also supported by Martín Saavedra, chief operating officer of Elifab, complementing that "we have seen that we are detecting bottom cracks at a very high and effective level. Previously, it was difficult to detect for top cameras given the angle. But now, with AI we barely miss them. We believe that at this minute there is no other technology that is working at this level".

Increase the pace with even faster processing speed.

Another of the advantages they have found is the speed of the grading process. In this regard, Contesse comments that "previously, when we received lots of fruit with very uneven quality, they had to be analyzed at very low speeds to identify defects. Today we can maintain the speed of the process thanks to True-AI, which has a very positive impact on throughput.

Good results in the box for all affiliated growers in the area

Cristopher Martinez, operations manager of Allegria Foods, also indicates that "in these weeks we have seen a very good result in the boxes, not only for us as Allegria Foods, but also for our customers, for whom we process fruit. The balance between speed of analysis and fruit selection is far superior to what we had before True-AI. We're convinced this technology will truly revolutionize cherry grading.

Making history as a proud global player in the cherry industry

Nicolás Carvallo (general manager Elifab Chili) also welcomes the recent True-AI technology created by Ellips. “The Elifab Cherry Grading Machines we supply to our cherry growers now offer unique capabilities, because no one else offers an AI-driven solution for cherries. This new cherry grading system is the most advanced and accurate that’s currently available in the world. Together with proud frontrunner Allegria Foods, we are now making history as cherry country Chile.”

The power of large amounts of data on cherry defects.

Carvallo explains: “True-AI is a detailed and collective database with defects, quality characteristics and answers to grading challenges like a-typical weather conditions. The technology consists of vast amounts of data from different cherry varieties collected during different seasons and conditions from our customers all around the world. It is built with hundreds of thousands of hand-labeled reference images to provide training information for the True-AI algorithms. The technology has been trained to find defects all on its own, making your life easier. All the grading parameter tasks are automated, saving your operator a lot of time.”