Owyhee Produce is a third generation, vertically integrated farm that grows and packs onions across more than 2,000 acres as part of its 10,000-acre operation. Based in the Idaho-Oregon border region, the company supplies high-end retailers and foodservice customers across the country with premium onions. Known for its high standards and commitment to consistency, Owyhee has built a strong reputation in the industry.

For years, onion grading at Owyhee Produce was a frustrating game of chance. “We’d have a mediocre lot – some good, some bad – and we’d be bouncing lots all the time,” recalls CEO Shay Myers. “That messes with your throughput, and it makes it hard to deliver the consistency customers expect.” With labor shortages, rising customer expectations, and the challenge of grading onions at scale, manual sorting simply wasn’t enough. Detecting internal quality issues was nearly impossible, risking costly rejections and weakening retailer relationships.

In 2019, the company turned to Ellips and invested in a high-capacity Elisam onion grader powered by Ellips grading technology. The system brought advanced defect detection, consistent internal and external quality grading, and scalable speed to their operation. The result? Dramatically improved consistency, significantly fewer rejections and a boost in efficiency that helped them increase market share and strengthen their position as a trusted supplier.

Then in 2023, Owyhee upgraded to the latest True-AI technology for even more accurate grading performance, improved defect detection, and further labor reduction. Shay Myers calls this technology a “game changer”. Not only for Owyhee but for the entire onion industry. “It’s helped us make a name for ourselves and set higher expectations with customers,” Shay says.

Watch all experiences of Shay in this video:

Following are just some of the improvements that Owyhee Produce achieved:

✅ Consistent high-volume throughput

With the ability to run between 36 and 42 tons per hour, Owyhee Produce scaled up its operation while maintaining reliability. Most days the system operates in the high 30s, enabling the team to handle large volumes with confidence and meet tight delivery schedules.

✅ Exceptional product quality that significantly reduces rejections

The combination of AI-driven grading and internal defect detection allows Owyhee to deliver a guaranteed product quality. Shipping over 3 million bags per year with virtually no quality complaints, this consistency has significantly reduced rejections and strengthened the company’s reputation with demanding customers. And, instead of switching lots to meet specs, operators can now simply adjust settings. Even average lots become retail ready. Shay adds, “With the internal capability of the Ellips system, we can basically assure that every single onion that goes in a bag is essentially perfect. That level of consistency is what opens doors and builds market share.”

✅ Greater efficiency with leaner teams

AI helped reduce the number of finish sorters from 2 per line to just 1, cutting labor needs by 4 to 5 people. Quality Control processes are now easier to manage, training is faster and team members can work more effectively, thanks to the system’s ease of use and reliability.

About Owyhee Produce

A vertically integrated onion powerhouse built on family, innovation and transparency

Owyhee Produce is a third-generation family-led farm and packing operation with over 2,000 acres of onions as part of a 10,000 acre farming footprint. With 11 family households working together, the company is built on a culture of hard work, shared values and relentless improvement. Their vertically integrated model means Owyhee controls every step of the process: farming, growing, packing, processing and shipping. This gives customers direct access to the source with fewer layers, better communication and complete supply chain transparency.

Driving consistency through technology and climate smart farming

As both farming and market expectations evolve, Owyhee invests in sustainable, climate conscious practices that reduce environmental impact while improving quality. Their use of AI powered grading technology helps maintain consistent sizing, defect free product and high throughput, even during volatile seasons. Owyhee produces over 3 million bags of onions per year, feeding millions of people with reliable quality and retail ready presentation. USDA Organic Certified across growing and packing, the company delivers both conventional and organic onions with the same high standards.

The Owyhee Difference

Whether it is fewer rejections, better market performance or a smoother buying experience, Owyhee believes that being different, thinking differently, farming differently and operating with full transparency is the key to long term success. It is not just about delivering onions. It is about delivering trust, quality and consistency in every layer.

Key challenges driving change

1. Inconsistent product quality across lots

Before implementing the Elisam grader with Ellips technology, Owyhee had to manually sort through different onion lots to find product that matched specific customer requirements. Some lots were good, some were mediocre, and the inconsistency made it hard to meet expectations. Switching between lots slowed down throughput and created operational inefficiencies. Even when the team made it work, it came at a cost to labor and quality control.

2. Risk of rejections and lost customer trust

Rejections were expensive and damaging. A single load with quality issues could hurt both short-term revenue and long-term relationships. In competitive markets, buyers do not wait for a second chance. Owyhee needed a solution that would reduce rejections and protect its reputation with every shipment.

3. Labor challenges and training limitations

Manual sorting required a large team with deep experience. Training new staff took time, and performance varied between individuals. During peak season, labor shortages made it difficult to keep up. Owyhee needed a way to reduce reliance on manual labor while making the sorting process easier to manage and scale.

4. Throughput limitations during high demand

Growing demand from retail and foodservice partners meant more volume and tighter deadlines. But without automation, the operation struggled to scale. Manual processes restricted daily throughput and created pressure during peak periods. The company needed faster, more reliable systems to keep up with growth.

5. Internal quality was anyone’s guess

Before automation, it was difficult to detect internal defects in real time. Manual processes lacked the precision and responsiveness needed to adapt quickly when problems arose. As Shay put it, “We love the folks who help hand-grade our onions, but they don’t have x-ray vision.” Without deeper insight into what was happening inside each onion, the team risked missed defects, inconsistent quality and unnecessary product loss. Owyhee needed technology that could see what people couldn’t, respond faster and keep quality high at scale.

Choosing the right partner and technology

As Owyhee Produce prepared to scale operations and meet rising quality demands, the leadership team knew they couldn’t rely on generic solutions. They needed technology built for onions, proven in the field, and tough enough to handle high volume without compromise.

Ellips and Elisam quickly stood out. In agriculture, word of mouth carries weight and the system was already delivering results for other top onion packers. Shay and his team visited facilities, saw the machines running, and spoke with operators. The performance was consistent, the feedback was clear, and the decision was easy.

“In our industry, word of mouth counts for a lot,” says Shay Myers, “We visited farms, saw the lines running, and talked with the people operating them. The machine did exactly what they said it would do from the start. This wasn’t about marketing claims. It was about machines that performed under pressure. Ellips didn’t promise inflated numbers. They hit the targets we needed. Day in, day out, in real-world conditions. That matters. A lot of suppliers promise throughput and quality that never shows up. Ellips gave us exactly what they said they would.”

What were the main motivations for choosing Ellips and Elisam?

1. High-speed, high volume capability

The system is designed to maintain consistent grading accuracy at high speed. Owyhee saw that they could process large volumes efficiently without sacrificing performance or product quality.

2. Advanced automation to streamline operations

The combination of intelligent software and precision engineering allowed the team to simplify sorting operations. With fewer manual steps, tasks could be completed faster, more consistently, and with less reliance on labor-intensive processes.

3. Superior external defect detection

With high-resolution imaging and calibrated lighting, the system identifies subtle cosmetic defects including staining, cuts, roots and tops. This level of detail supports precise packout control and delivers consistently attractive product.

4. Reliable internal quality detection

The Ellips technology offers two advanced inspection technologies to guarantee internal quality. First, a set of near-infrared (NIR) cameras captures 10 images of each onion, scanning 2 to 3 layers deep to detect bruising, mold, decay, and sunburn. Then, a second system projects high-powered light through the onion bulb, exposing core-level issues like dry-scale, translucency, and internal rot. Together, these technologies give Owyhee complete visibility into what’s happening inside every onion. No surprises when cutting them in half.

5. Engineered for durability and long-term efficiency

The Elisam machine is built to run hard, day after day. Its mechanical reliability, ease of maintenance, and efficient design made it a strong operational fit for Owyhee’s long-term growth and ROI goals.

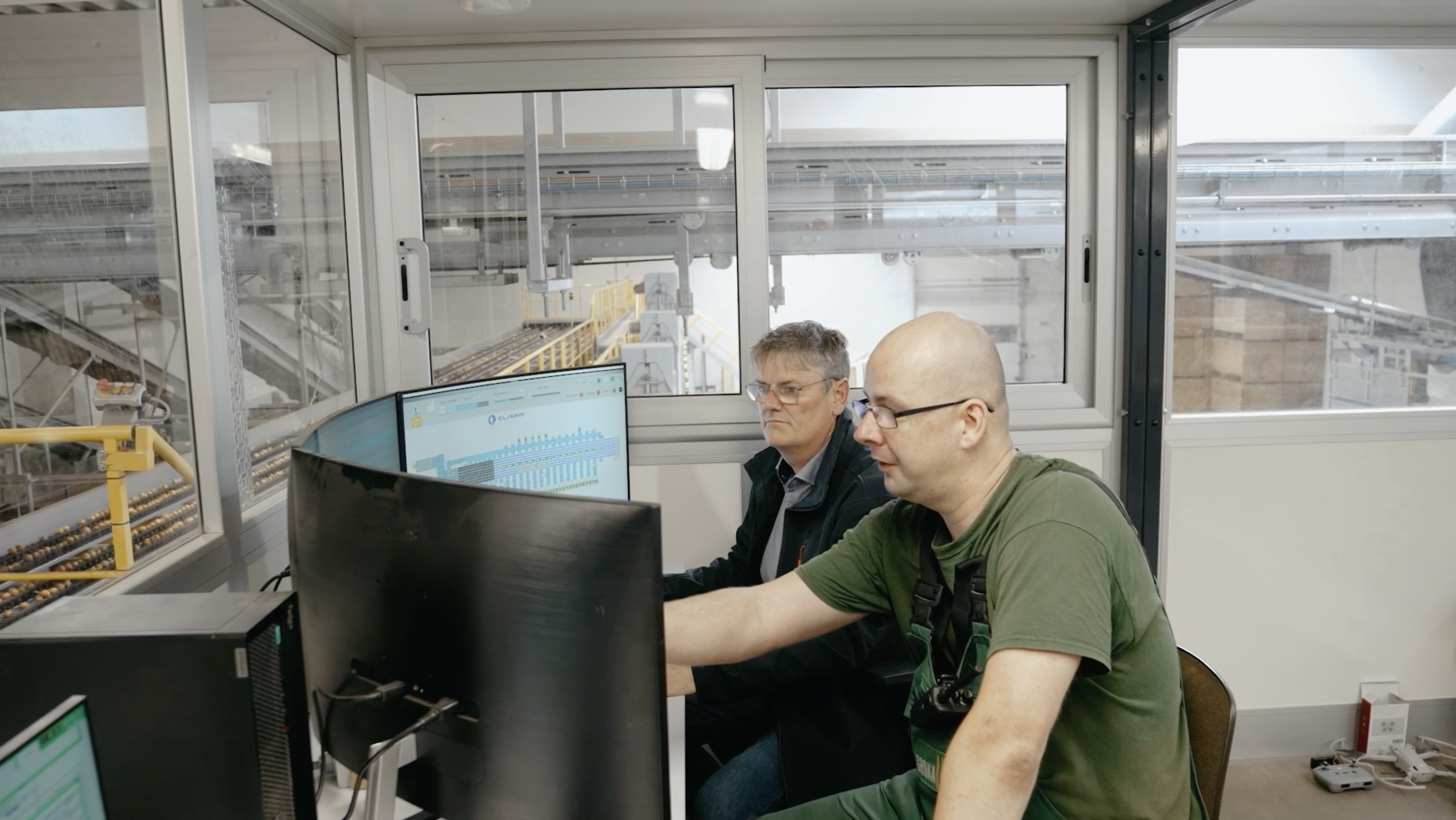

Strategic partnership and support

Shay made it clear that no installation is ever perfect, but what matters is the support that follows. From day one, Ellips was a hands-on partner. Present during installation, involved in training, and responsive to real-world challenges.

The Owyhee team regularly contacts Ellips to report rare defects, suggest improvements, and work with developers to optimize detection. This open feedback loop has been key to fine-tuning the system and driving long-term success.

Results

✅ Higher throughput with consistency

Owyhee Produce now runs between 36 and 42 tons per hour on their Elisam line, depending on the size and quality of the onions. Most days, throughput sits consistently in the high 30s. That efficiency has allowed the company to handle large volumes without sacrificing quality.

✅ Stronger product consistency

Before the system, Owyhee had to sort through different lots to find product that matched customer needs. Now, they simply adjust settings and let the machine ensure every onion meets spec. This ability to make even average lots perform at a high level has been key to building customer trust.

✅ Reduced sorters and more efficient labor

The AI upgrade reduced the number of finish sorters from two per line to one, cutting labor needs by four or five people across the operation. The Quality Control team, led by an operator who has been there since day one, now works more efficiently and can train new staff more easily.

✅ Fewer rejections and stronger reputation

Rejections used to be expensive and damaging. Now, with consistent output and internal defect detection, Owyhee delivers with maximum accuracy, shipping over 3 million bags per year with virtually no quality complaints.

✅ Increased market share through consistency

With the ability to deliver consistent sizing, internal and external quality, and fewer rejections, Owyhee has grown its presence in competitive markets. Retail and foodservice buyers now reward that reliability with more volume and long-term trust. “Better technology has definitely given us more market share,” Shay says. “When customers know that every single time the sizing and internal and external quality will be consistent, they’ll pay a little more. But more than anything, they reward us with more loads.”

Shay reflects, “Sorting technology and consistency are opening doors all the time. I love looking at the year-end spec sheets: 4,000 loads, 3 million bags, and only about 20,000 issues. That’s 99.9% accuracy, which is amazing.”