Elita, a family-owned business founded in 2012 in Veria, Greece, has grown into a major exporter of high-quality fruit, supplying premium kiwifruit to more than 30 countries worldwide. As global demand increased, Elita needed a solution to scale its processing capacity while maintaining the highest quality standards.

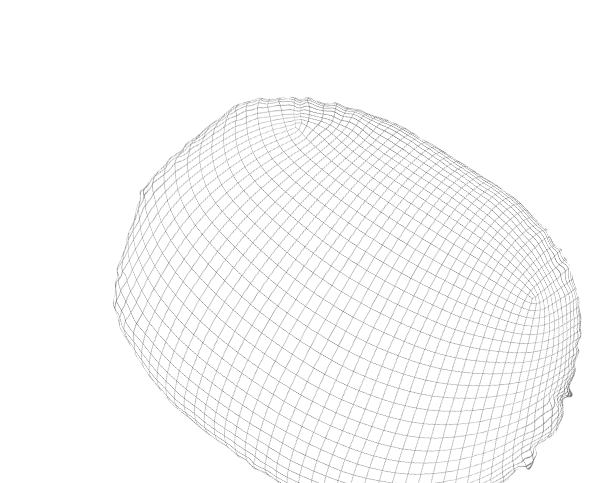

Elita invested in the Elisam kiwi grading machine powered by Ellips True-AI technology. The result? A more efficient operation capable of handling higher volumes and delivering consistently high-quality kiwifruit to meet strict export requirements.

The solution now gives Elita full control over capacity, quality, and efficiency—scaling up without adding complexity.

Following are just some of the improvements Elita achieved:

✅ Increased processing capacity — now processing up to 9 million kilos of kiwifruit annually and packing up to 100 tons per day to meet global demand.

✅ Improved sorting accuracy — faster and more precise sorting ensures consistent export-quality kiwifruit and reduces the risk of defects reaching the market.

✅ Enhanced operational efficiency — with AI technology supporting skilled operators, Elita handles larger volumes without increasing labor dependency.

Watch all experiences of Moses in this video:

About Elita

A family business with a global reach

Elita was founded in 2012 by brothers Dionysis and Mimis in Veria, Greece. What started as a local family business has grown into a leading fruit exporter, supplying high-quality produce to over 30 countries worldwide. Elita’s product range includes a wide selection of fresh, seasonal fruits, such as kiwis, strawberries, cherries, peaches, apricots, mandarins, plums, apples, and oranges.

Focused on quality and trusted partnerships

Elita is committed to delivering exceptional fruits, with a strong focus on kiwifruit. Nearly all kiwi production is of the Hayward variety, sourced primarily from the renowned growing regions of Pella, Imathia, Pieria, and Kavala. By working closely with selected growers in Greece and applying strict quality controls, Elita ensures that every product meets the highest standards for its global customers.

Through continuous monitoring and expert agronomist supervision, Elita carefully manages every step of the process—from harvest to delivery. Harvested at the optimal stage of ripeness and stored under ideal conditions, Elita’s fruits consistently arrive fresh and meet the high-quality standards demanded by international markets.

Key challenges driving change

Elita was experiencing strong growth in its kiwifruit exports, with demand rising rapidly across more than 30 international markets. To keep up, the company needed to increase processing volumes while continuing to deliver the consistent, high-quality products its customers expect. However, the existing sorting process and capacity made it challenging to scale effectively.

1. Manual sorting couldn’t meet growing demand

Elita faced the challenge of handling significantly larger volumes of kiwifruit. Sorting by hand was time-consuming and couldn’t deliver the speed needed to meet production targets. To process higher tonnages efficiently, people and machines needed to work together.

2. Inconsistent quality and limitations of manual sorting

Strict export standards required consistent product quality, but manual sorting made it difficult to meet these standards at scale. The process was not only slower but also less precise, increasing the risk of defects slipping through and causing rejections in critical markets.

3. Detecting subtle defects to meet export standards

Certain defects are difficult to detect manually but are essential to maintaining the quality expected by international customers. These include issues such as sunburn, skin cracks, russet, shape-related defects, scar tissue, rot, firmness, softness, and more. To reliably meet export standards, Elita needed a technology-driven solution capable of identifying these defects with greater accuracy.

Why Elita chose Elisam and Ellips AI technology

Elita selected the Elisam-Ellips solution to support its growth ambitions and meet the increasing demands of international markets. The decision was based on three key factors:

1. AI-powered sorting for consistent quality

To meet strict export standards and ensure a consistently high-quality product, Elita needed to move beyond manual sorting. The advanced AI-powered grading system delivers faster, more accurate sorting and ensures that every kiwifruit meets the required specifications.

2. Scalability and performance to handle higher volumes

With rising global demand, Elita required a solution that could efficiently handle larger production volumes. The combination of advanced technology and optimized workflows allows the company to increase throughput without adding operational complexity or expanding its workforce.

3. A trusted and experienced technology partner

Elita chose Elisam and Ellips for their proven expertise in fruit sorting technology and their strong reputation as industry leaders. This partnership provides Elita with a future-proof solution that supports both current production needs and long-term growth ambitions.

4. One technology for multiple fruit types

Beyond kiwifruit, Elita takes full advantage of the flexibility of Ellips True-AI grading technology. The Elisam AI grader is also used for stone fruits, and the company operates a dedicated Elifab machine for cherries—all powered by the same advanced AI software. This unified approach enables Elita to maintain consistent quality standards across its diverse product range while streamlining operations and maximizing efficiency.

The results speak for themselves

✅ Increased processing capacity — With the Elisam AI grader, Elita now processes up to 9 million kilos of kiwifruit annually and packs up to 100 tons per day, keeping up with rising global demand.

✅ Improved sorting accuracy — AI-powered grading delivers faster and more precise sorting, ensuring consistent export-quality kiwifruit and reducing the risk of defects reaching the market.

✅ Enhanced operational efficiency — By combining advanced technology with skilled operators, Elita optimized its workflow, enabling people and machines to work together more effectively and handle larger volumes without increasing labor dependency.