African Blue, one of Morocco’s leading blueberry producers, is scaling fast. Since 2007, the company has stood at the forefront of the country’s blueberry industry. With 345 hectares already in production and plans to replant over 700 hectares using Costa’s latest premium varieties, African Blue is preparing for a major volume increase in the years ahead. With the ambition to double production within five years, the commitment to quality and innovation has never been stronger.

The company also benefits from one of the world’s longest blueberry production windows, running from late October through early June. It operates farms in both the north and south of the country, where climate and harvest conditions can vary significantly. Together, these factors offer strong commercial advantages but also increase the complexity of maintaining consistent quality throughout the season.

At the same time, growth brings new pressure. The existing hand-sorting process was reaching its limit. Especially when it came to removing soft fruit, handling defects, preserving bloom appearance or meeting detailed customer specifications for jumbo sizes, acidity, shelf life and delivering precise sizing for customer-specific pack formats.

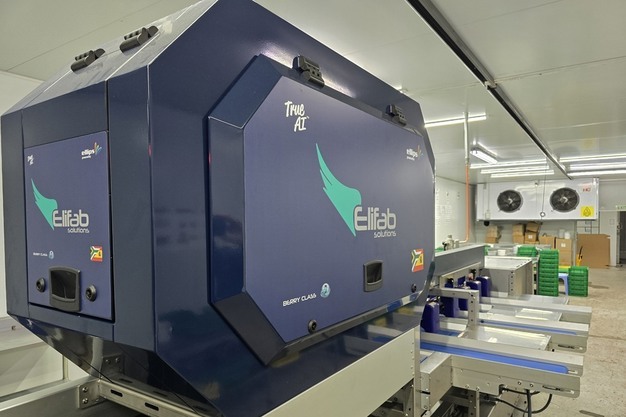

To unlock higher productivity and protect premium quality at scale, African Blue turned to a 12-lane Elifab blueberry grader powered by Ellips True-AI, paired with three Mat Exakta punnet and clamshell fillers

This high-speed solution allows the team to process more blueberries per hour, sort with greater accuracy, and pack a broader range of formats. All while preserving the visual and structural quality that premium markets expect.

The result?

Faster throughput, sharper quality control and a scalable, future-ready packhouse operation built to handle Morocco’s booming blueberry volumes with confidence.

Following are just some of the improvements that African Blue achieved:

✅ Increased throughput with processing up to 4 ton per hour

Replacing the output of three manual lines and enabling a full shift to bulk harvesting for all farms delivering to the Elifab-equipped packhouse

✅Highly accurate defect detection for premium quality and shelf-life optimization

Soft fruit, dehydration, acidity and bloom sensitivity are now sorted with precision, ensuring stronger arrival quality for long-distance exports to Asia and the USA

✅ Consistent grading and sizing to meet diverse market requirements

Accurately sorting fruit by size and quality into customer-specific categories such as jumbo (18+ mm), super jumbo (22+ mm), 14+, and 16+, supporting premium product lines and pack formats across regions

About African Blue

A leading force in Moroccan blueberry production

African Blue operates in both the north (Moulay Bousselham and Larache) and the south (Messa, near Agadir). Since starting exports in 2013, the company has built a strong reputation for delivering high-quality blueberries to demanding international markets. African Blue is now majority owned by Costa Group, Australia’s leading grower and marketer of fresh fruit and vegetables. Costa is globally recognised for its blueberry plant breeding program, with Costa varieties licensed in regions including Australia, the Americas, Africa and Asia.

Strategic location with strong market access

African Blue is well-positioned to serve global markets thanks to Morocco’s proximity to Europe, efficient logistics, and strong infrastructure. Just as important is the team’s deep understanding of customer expectations, product quality and blueberry production.

The country’s diverse climate zones create ideal growing conditions for a wide range of premium varieties. Making it possible to supply high-quality fruit consistently from late October through early June.

Scaling for the future with exclusive Costa genetics.

African Blue currently manages 345 hectares, with plans to replant over 700 hectares using Costa Group’s latest proprietary varieties. As a subsidiary of Costa Group, African Blue benefits from exclusive access to premium genetics known for their flavour, size, firmness and shelf life. Traits that consistently meet the highest export standards.

These genetics support strong performance across both retail and international markets. The company exports to leading retailers and distributors across Europe and Asia. Including the UK, Germany, the Netherlands, France, Belgium, Singapore, Hong Kong and Malaysia and has recently started shipments to the USA.

Key challenges driving change

African Blue was entering a period of rapid growth. With a clear ambition to double production in the coming five years, the team faced a familiar dilemma. How do you scale throughput and maintain top quality at the same time, across a long and complex season? Relying on manual grading alone was reaching its limit.

1. Manual sorting couldn’t guarantee export quality

As customer demands increased, so did the pressure on precision. Clients across Europe and Asia expected exact sizing, longer shelf life, and flawless presentation with every shipment. But traditional sorting methods struggled to deliver the consistency required.

Defects like softness or dehydration were difficult to detect manually. At the same time, preserving bloom, a key visual quality factor in premium markets, was difficult to manage with manual handling.

For premium markets and long-distance exports like Asia and the USA, even minor issues could mean rejected shipments or lost value. Field teams were already sorting during harvest, followed by another round of manual grading in the packhouse. It was laborious, time-consuming, and still not consistent enough.

2. A long season means shifting conditions

African Blue benefits from one of the world’s longest production windows, stretching from late October to early June. It’s a major strategic advantage, but one that also brings complexity. Over such a long season, harvest conditions change. Fruit size, firmness, and defect levels fluctuate. Manually keeping quality stable from start to finish was becoming increasingly difficult. This challenge was amplified by the company's multi-region setup. With farms both in the north and south of Morocco, harvest timing and climate conditions can differ significantly

3. Rising volumes called for higher throughput

Manual lines were simply not fast enough to keep up. Sorting operations were already running at full capacity, with grading taking place both in the field and in the packhouse. With volumes set to double over the next five years, relying on the same setup was no longer realistic. It was not feasible to expect the team to process significantly more fruit in the same amount of time without smarter technology.

The 12-lane Elifab grader delivered the step change in productivity the team needed. It also enabled a full shift to bulk harvesting, which significantly improved efficiency during peak harvest weeks.

4. A 24-hour window to deliver freshness

Exporting premium blueberries isn’t just about quality. It’s about speed. With customer timelines tightening, African Blue follows a strict harvest-pack-export model, where fruit is picked, sorted, packed, and shipped within 24 hours. That requires more than speed. It demands total reliability from both people and technology.

The new grader plays a key role in maintaining that pace. It supports continuous production, avoids bottlenecks, and ensures fruit is export-ready by the end of the day. This speed isn’t about cutting corners. It’s about protecting shelf life, arrival quality, and ultimately, brand reputation in highly demanding markets.

Choosing the right partner and technology

Switching from manual to machine grading was a big decision for African Blue. The team needed a solution that could handle increasing volumes, preserve quality, and adapt to shifting customer requirements across global markets.

Fortunately, the decision was supported by experience from within the Costa Group. A proven installation in Australia already showed the reliability of the Elifab grader powered by Ellips AI. Companies in South Africa and Zimbabwe shared similar positive results with Elifab machines on Costa varieties. These combined experiences strengthened African Blue’s decision to move forward.

At the same time, the team carefully compared technologies, visited reference sites, and spoke with other users to validate their choice.

The final choice?

A 12 lane Elifab grader powered by Ellips True AI, paired with three Mat Exakta punnet filling systems. A fully integrated grading and packing system designed to maximize throughput and protect premium quality at scale.

What were the main motivations for choosing Ellips-Elifab-Mat Exakta?

1. Productivity to support rapid growth

With harvest volumes increasing year over year, African Blue needed to scale its grading operation without adding complexity or relying on multiple manual lines. The Elifab 12-lane grader provided the productivity the team was looking for. It matched the throughput of several manual lines combined and enabled a full shift to bulk harvesting across farms supplying the packhouse. For a business focused on growth, this level of efficiency was essential.

2. Accurate defect detection with True-AI

One of the major drivers behind the decision was the need for more reliable defect detection. Manual sorting struggled to consistently detect soft fruit and dehydration. Especially during the more challenging later stages of the season. The Ellips True AI grading system offered a much more precise and consistent way to identify and remove these defects, while still preserving fruit that was suitable for packing. This gave the team better control over overall quality and reduced unnecessary waste.

3. Gentle handling to preserve bloom

In many of African Blue’s key export markets, bloom is a major visual indicator of freshness and quality. Preserving this delicate feature throughout the sorting process was non-negotiable. One of the reasons the Elifab solution stood out was its ability to maintain bloom, even at high speeds. This gave the team confidence that their fruit would meet the appearance expectations of premium customers across regions.

4. Flexibility for different customer programs

African Blue serves a wide range of markets, each with its own specifications for size, firmness and packaging mix. The Ellips software platform gives the team the flexibility to create detailed sorting profiles and quickly switch between programs. Whether that means a specific size range, a custom mix, or a tailored packaging format.

Just as importantly, the machine enables operators to fine-tune settings in real time based on fruit condition, customer requirements, and productivity goals. Whether prioritizing speed, defect targeting or output volume, the intuitive software puts full control in their hands. This adaptability helps the team respond fast to shifting demands without compromising efficiency or consistency.

5. End-to-end integration for seamless packing

The decision to pair the grader with Mat Exakta’s in-line punnet fillers created a fully integrated system from sorting to final packaging. The automation helps maintain a continuous flow and reduces manual handling. More importantly, the packing solution offers flexibility to handle all common formats including punnets, clamshells, buckets and cartons in plastic, paper or cardboard. Whether packing for retail or export, the system delivers high-speed, accurate weighing, consistent lid placement and clean labelling. This allows the team to run efficiently with minimal labour while meeting a wide range of market-specific requirements.

6. Compact footprint to fit existing packhouse setups

Space is always a consideration when upgrading technology. One of the standout advantages of the Elifab grader is its compact footprint combined with the highest processing capacity per lane in the market. Compared to other solutions on the market, it’s smaller and more space-efficient. That made it a better fit for African Blue’s packhouse, allowing them to scale throughput without needing to expand the building or reconfigure the entire layout.

Ongoing learning and team training

Adopting a new grading system is more than just installing a machine. It’s a learning journey. From the start, African Blue treated the technology as a dynamic tool that improves over time through experience and insight. Within a few weeks, the team noticed a clear shift in performance. Not just from the machine, but in how operators used it.

With hands-on support and training, operators quickly became more confident in setting parameters, adjusting performance, and applying the system to real-world conditions. As the season progressed, they kept improving how the machine was used. For African Blue, this adaptability is what makes the system powerful. It keeps getting better with every batch, every lesson, and every decision.

Results

With the new Elifab grader in place, African Blue has unlocked a new level of performance. Both in terms of operational efficiency, flexibility and product quality. The combination of Elifab, Ellips and Mat Exakta has helped the team move faster, sort more precisely and meet the growing demands of premium export markets with consistency and confidence.

Following are just some of the improvements that African Blue achieved:

✅ Increased throughput with processing up to 4 tonnes per hour

Replaced the output of three manual lines and enabled a full shift to bulk harvesting for all farms delivering to the Elifab-equipped packhouse.

✅ Highly accurate defect detection for premium quality and shelf-life optimization

Soft fruit, dehydration, acidity and bloom sensitivity are now sorted with precision, ensuring stronger arrival quality for long-distance exports to Asia and the USA.

✅ Consistent grading and sizing to meet diverse market requirements

Accurately sorts fruit by size and quality into customer-specific categories such as jumbo (18+ mm), super jumbo (22+ mm), 14+, and 16+, supporting premium product lines and pack formats across regions.

✅ Fewer rejected packs and more confidence in export shipments

By removing compromised fruit early in the process, the system helps reduce the risk of poor arrival quality. Especially important for distant markets with long transit times.

✅ Higher packing efficiency across multiple formats

Thanks to Mat Exakta’s in-line automation, African Blue now packs more formats faster. With accurate weights, secure lids and correct labels, all with fewer people on the line.

A long-term investment strategy already underway

African Blue sees this investment as more than just a solution for immediate gains. The grading and packing technology are a key part of their long-term strategy to scale production, improve efficiency and protect product quality as volumes grow. A second Elifab-Ellips line is already being planned for the 2026–2027 season, with a third expected in 2028. These steps are designed to increase capacity, expand the product mix and reduce pressure on the existing operation. All while keeping customer satisfaction and product consistency at the highest level.

Connecting data from field to packhouse

Looking ahead, African Blue is also working to unlock more value through data. The team is implementing a system that links farm and packhouse operations, allowing real-time analysis of fruit quality, machine performance and sorting parameters across different varieties and regions.

Access to machine data in an analysable format, such as Excel or Power BI, will make it easier to fine-tune performance. It will help the team adapt quickly to changing harvest conditions, variety-specific behaviour and market demands. This ability to align machine settings with real-time feedback is expected to improve consistency, reduce waste and support even smarter decision-making in the seasons ahead.

By connecting people, processes and data in a more intelligent way, African Blue is building a more adaptive, responsive and scalable operation. Ready for the next wave of growth.