Located in the heart of South Africa’s Northwest Province, Handvol Boerdery may be a family-run farm, but it’s playing in the big leagues when it comes to packhouse innovation.

With exports growing, global standards rising, and seasonal variation affecting grading, the team needed a way to maintain premium-grade performance. They also had to keep labour costs manageable, product quality consistent, and speed high during peak weeks.

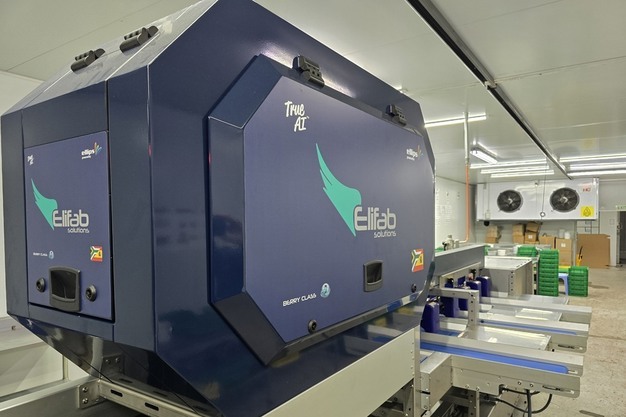

To unlock higher productivity and protect premium quality through advanced defect detection, Handvol Boerdery turned to a 2-lane Elifab grader powered by Ellips True-AI.

“We expected more efficiency,” says Production Manager Cat Squire, “but we didn’t expect it to completely change the rhythm of our packhouse.” Operating the Elifab is surprisingly straightforward. Within a few days, our team was running the system confidently and efficiently.

From the very first week, we noticed how precisely the system performed. The production readings were remarkably accurate, giving us a clear picture of pack-out and grade distribution in real time.

One of the biggest surprises was how effortlessly the Elifab handled variety changes. Switching between different cultivars, berry sizes, and quality settings happens smoothly, without the need for long recalibrations or technical delays.

One thing we quickly learned: this machine rewards cleanliness. When kept clean, its sizing precision, color consistency, and defect detection remain spot-on. The AI system maintains accuracy even when market requirements shift and specific grades are in demand. Once the program is set, you can walk away confident that the results will stay consistent from start to finish.

The result?

A faster, more efficient, and more consistent packhouse operation that delivers export-quality blueberries with confidence.

Results

Following are just some of the improvements that Handvol Boerdery achieved:

✅ Up to 400–600 kg per hour throughput, depending on berry size

The 2-lane Elifab system comfortably handles 400 kg of blueberries per hour with smaller fruit (±1.9g average berry weight). With larger or jumbo berries (3g or more), throughput can reach up to 600 kg per hour. This ensures consistent productivity without bottlenecks.

✅ Labour reduced by nearly 50% with no compromise on quality

Thanks to advanced defect detection and automation, the packhouse team cut manual sorting in half while still meeting export standards for bloom, firmness and shelf life.

✅ 24/7 grading consistency with real-time pack-out insights

Accurate data helps operators monitor and optimise performance throughout the day. The team has full visibility into grade distribution and pack-out, batch by batch.

✅ Advanced defect detection that boosts export confidence

The AI accurately removes defects like softness, shrivel, red berries, rain splits and scars, helping the farm maintain premium export quality even in mixed batches.

✅ Fast variety switching with zero downtime

Changing between cultivars, berry sizes and customer specs is quick and seamless. No recalibration is needed, which keeps operations flowing during peak periods.

Exceptional defect detection with Ellips True-AI

“The management at the Handvol Boerdery packhouse singled out the Ellips True-AI defect detection as a standout feature.

It identifies and separates:

- Internal softness

- Shriveled berries (nearly impossible to detect with the human eye and a recurring issue in South African blueberry packhouses)

- Dry scars and rain-related splits

- Picking scars and immature (red) berries

- Fruit discoloration and mold

This accuracy has allowed us to maintain export-level standards even with mixed-quality batches or end-of-season fruit, says Cat.”

Calyx and detection with 100% accuracy

“The main difference with EllipsTrue-AI is that it can recognise the calyx and the stem with 100% accuracy,” explains Rory Cole - Flowpack, local Elifab-Ellips partner in South Africa. “Sometimes rust on the remnants of petals in the calyx can be misidentified as defects on the body, actually taking out good fruit from class one. With True-AI, if that berry turns, it will still recognise the calyx a hundred percent of the time.”

Powered by the world’s largest fruit image database

“It is the depth of annotation that Ellips added over the course of years to its giant bank of images, says Rory. Gathered from over 3,500 packhouses where it’s in operation globally. That stands out, Cole adds. This has enabled the development of highly specific algorithms tailored to different fruits and vegetables, including apples, citrus, cherries, blueberries, onions, dates, potatoes and more.”

The gentlest handling from the Elifab grader

“Another highlight is the gentle handling, according to Cat. The small drop distances and soft sorting at the exits minimize bruising. A critical factor for preserving the quality, bloom and shelf life of premium blueberries.”

Delivering the highest throughput to keep up with the demands

“Even with smaller or more delicate fruit toward the end of the season, the 2-lane system comfortably processes 400 kg of berries per hour. When running larger fruit, like jumbo berries of 3 grams or more, we’ve reached throughputs of up to 600 kg per hour. The reduction in manual sorting has been dramatic. We’ve managed to cut our labour requirement by nearly half without sacrificing quality.”

The hidden gem: a fully self-cleaning roller steamer

“Another standout feature is the built-in roller steamer. It’s fully self-cleaning: just start the cycle, step away, and within 20 minutes the rollers are clean and ready for the next run. This small detail saves time and keeps roller maintenance effortless.”

A smart investment that delivers every day.

“For any packhouse looking to modernize its blueberry line, the Elifab grader, driven by Ellips True-AI delivers an impressive balance of accuracy, efficiency, and gentle handling. Its ability to adapt between varieties, maintain consistent quality, and reduce labour costs makes it a valuable investment for blueberry packhouse operations, concludes Cat Squire.

At Handvol Boerdery, it has become the heart of our packhouse. Reliable, intelligent, and a true partner in delivering top-quality fruit.”

Your local Elifab Partner in South Africa: Flowpack

World-class support. In your language. Just around the corner.

✅ Complete packhouse solutions

Extensive experience in the fruit industry of South Africa, Namibia and Zimbabwe. Dealer of Elifab, Elisam, Ellips AI, retrofits, and Mat Exakta packing systems. For end-to-end grading, sorting, and packing solutions.

✅ Tailored sales and consultation

From first concept to installation, every solution is designed around your produce, capacity, and operational goals. Starting from the very first conversation.

✅ Local service & support

From installation to spare parts and solving issues. Your local agent is your first call. Fast answers. Personal contact. Ongoing commitment.

Rory Cole

📧 rory@flowpack.co.za

📞 +27 (0)82 294 2260

http://www.flowpack.co.za/