Medjool Village is Jordan’s largest and only fully vertically integrated grower, packer, and exporter of Medjool dates. As the country’s biggest date farm and one of its most advanced producers, it has become an industry leader in quality, reliability, and flexibility in the premium Medjool date industry. From its 500-acre operation in the fertile Jordan Valley, the company delivers high-grade dates to some of the world’s most demanding markets. Including partnerships with the UK’s top four supermarkets. But its reach doesn’t stop there. Medjool Village also exports to the wider MENA region, including Kuwait, Qatar and Lebanon.

As demand grew and customer specifications became more complex, manual sorting simply couldn’t keep up. Inconsistent grading, limited capacity and seasonal labor shortages made it difficult to deliver on time and at the required standard. UK retailers demand 100% quality consistency, zero defects, and full traceability to deliver top-quality to their customers and meet strict EU regulations, including detailed documentation and testing. For a company built on reliability and product excellence, these bottlenecks threatened hard-won partnerships. To stay competitive and scale with confidence, Medjool Village turned to automation in their grading process.

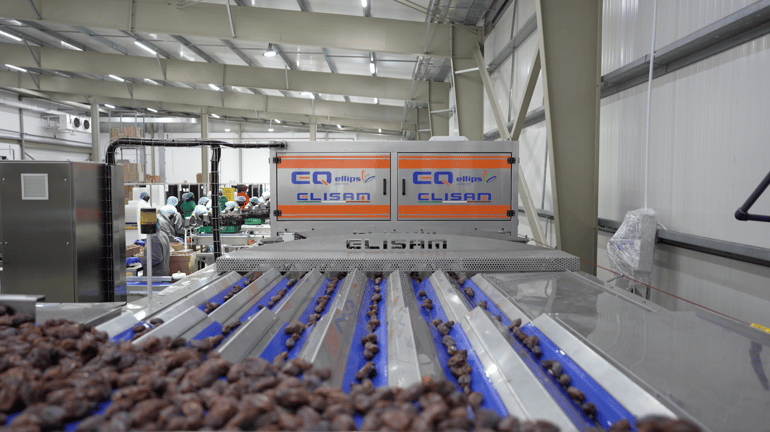

The solution came in 2019 with the investment in a high-performance six-lane Elisam date grading machine, powered by Ellips technology. It sorts by size, shape, skin separation, defect detection and moisture content with exceptional accuracy and speed. The result? 98% product consistency, 30% less labor, and the confidence to serve premium export markets without compromise.

Watch all experiences of Jude Nubalsi this video:

Following are just some of the improvements that Medjool Village achieved:

✅ Massive increase in throughput

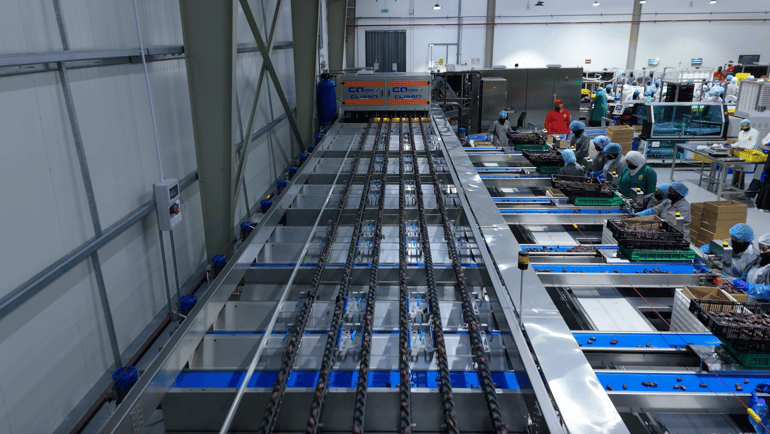

With a sorting capacity of 3.5 tons per hour, Medjool Village scaled from sorting just 4 tons per day manually to handling that volume every hour. The Elisam grader enabled faster, more reliable processing. Making it possible to meet tight export deadlines, serve exclusive retail customers, and maximize the value of every harvest.

✅ Exceptional product consistency and higher value

With high-precision sorting on size, skin separation and moisture content, Medjool Village now maintains a 98 percent consistency rate across 21 distinct quality grades and multiple size formats. Before automation, manual sorting limited them to around 10 rough categories. Now, advanced grading enables precise product segmentation, better alignment with customer specs, and significantly less waste. This improved accuracy translates into more value from every harvest, meets the strict standards of top-tier retailers including the UK’s largest supermarket chains, and secures up to 30 percent higher premiums in key export markets.

✅ Streamlined operations with reduced labor

Automation allowed Medjool Village to reduce manual labor needs by 30%, while eliminating bottlenecks and inefficiencies during peak season. With faster turnaround, fewer errors, and consistent quality output, the company now operates with greater speed, less stress, and total confidence in every shipment.

About Medjool Village

A leading force in premium Medjool date production

With deep roots in the Jordan Valley and over a decade of experience, Medjool Village has grown into the country’s most advanced and fully integrated Medjool date producer. The company manages more than 500 acres of farmland and 30,000 palm trees, combining scale with a dedicated focus on quality through advanced farming practices and compliance with global certifications. Ensuring every date meets the highest standards from field to export.

Its location at the lowest point on Earth provides ideal conditions for cultivating dates with exceptional taste, texture, and shelf life.

Full control from field to facility

Medjool Village manages the entire value chain in-house: farming, harvesting, packing, sorting and export. Its 15,000 m² packing house, located close to the plantations, features advanced optical sorting systems and 3,000 tons of cold storage capacity. With 21 product grades and multiple size formats including premium, delight, classic and extra juicy categories, ranging from super jumbo to small, the company delivers tailored solutions to meet the exacting requirements of international customers, with full traceability and freshness guaranteed.

A growing global brand

Medjool Village exports to over 20 countries across five continents. Typical customers include major supermarkets, wholesalers, and distributors. It is the exclusive Medjool date supplier to the UK’s top four supermarkets and serves premium buyers in the MENA region, including Kuwait, Qatar and Lebanon. The company continues to grow its international presence by building long-term partnerships through product excellence, dependable service and a clear focus on customer success.

Key challenges driving change

1. Meeting international quality standards

Before upgrading, Medjool Village relied on manual sorting, which limited them to roughly 10 broad quality categories. This made it difficult to meet the strict and detailed specifications of high-end export partners. Especially UK supermarkets requiring flawless consistency, zero defects (no black mold, bruised or sour dates), and full traceability to comply with EU regulations. Manual sorting also made it harder to detect key quality indicators like skin condition and moisture content, which impacted product reliability and led to unnecessary food waste and lost premium pricing opportunities.

2. Labor shortages during peak season

Every harvest season came with the same headache: not enough skilled hands to keep up. Finding and training temporary workers to sort with precision was a recurring challenge. Labor shortages slowed down operations, delayed shipments and forced the team to work under pressure. Especially when fulfilling orders for major supermarket partners with nonnegotiable delivery schedules. The pressure to deliver quickly without sacrificing quality became increasingly unsustainable without automation. Medjool Village was at constant risk of missed deadlines and damaged customer trust.

3. Limited capacity to meet growing demand

Manual sorting capped the operation at just 4 tons per day, which was nowhere near enough to keep pace with rising export volumes. Each season brought more demand but no way to scale output without slowing things down. Without faster and more efficient systems in place, Medjool Village risked missing out on growth opportunities and falling short in high-value international markets.

Choosing the right partner & technology

When Medjool Village set out to upgrade their sorting operations, they needed a solution that could deliver consistent quality at scale without disrupting daily operations. After evaluating options, they chose Ellips grading technology and the Elisam sorting machine for its proven accuracy, expertise in fresh produce, and strong fit with their export-driven goals. According to CEO Jude Nabulsi, it wasn’t just a new investment. It was a strategic shift that reshaped how Medjool Village delivers excellence at scale.

What were the main motivations for choosing Ellips-Elisam?

1. Proven accuracy to meet exacting quality standards

Accuracy was a top priority. Medjool Village chose Ellips-Elisam for its ability to sort with precision and consistency, which is essential for meeting the strict specifications of high-end export customers. The system also gave the team more flexibility to adapt to new market needs by offering greater control over product segmentation.

2. Higher capacity to handle seasonal pressure

3. Reduced dependency on manual labor

4. A fully integrated solution tailored to their process

5. Technology and expertise aligned with long term goals

Strategic partnership and support

For Medjool Village, choosing Ellips Elisam wasn’t just about upgrading machinery. It was about working with a partner they could rely on long after installation. The local dealer in Jordan, Sami Abu Hamdeh, played a key role in ensuring a smooth transition, offering responsive support and practical expertise throughout the process.

From early training to fine tuning the system, the collaboration with the Ellips - Elisam team exceeded expectations. Thanks to their user-friendly technology and comprehensive onboarding, the Medjool Village team fully adopted the new system within weeks with minimal disruption.

That support didn’t stop after going live. Whenever a question came up or an issue needed solving, the Ellips - Elisam team responded quickly, even on weekends or outside office hours. As one team member put it, "I can't think of a day where we couldn't reach them." This level of availability and service gave Medjool Village the confidence to operate without interruption and to keep improving season after season.

.png?width=770&height=433&name=Partnership%20Medjool%20Village%20Elisam%20Ellips%201%20(1).png)

Results

The move to automation marked a major turning point for Medjool Village. After implementing the Elisam date grader with Ellips grading technology, the company quickly saw improvements across performance, product quality and efficiency.

From faster sorting to fewer errors and better utilization of the full harvest, the change has been both operational and strategic.

Following are just some of the improvements that Medjool Village achieved:

✅ Massive increase in throughput

With a sorting capacity of 3.5 tons per hour, Medjool Village scaled from sorting just 4 tons per day manually to handling that volume every hour. The Elisam grader enabled faster, more reliable processing. Making it possible to meet tight export deadlines, serve exclusive retail customers, and maximize the value of every harvest.

✅ Exceptional product consistency

By sorting with high precision on size, skin separation, and moisture content, Medjool Village now maintains a 98% consistency rate across 21 quality grades and multiple size formats. This level of reliability ensures the company meets the exacting standards of top-tier retailers, including the UK’s largest supermarket chains.

✅ Streamlined operations with reduced labor

Automation allowed Medjool Village to reduce manual labor needs by 30%, while eliminating bottlenecks and inefficiencies during peak season. With faster turnaround, fewer errors, and consistent quality output, the company now operates with greater speed, less stress, and total confidence in every shipment.

✅ Higher product utilization and stronger pricing

Manual sorting often led to unnecessary product loss and missed quality potential. With improved accuracy and consistency, Medjool Village now captures more value from every harvest. This includes reducing waste, matching products to the right segments, and securing up to 30 percent higher premiums in key export markets.

✅ More flexibility to serve different market needs

Before automation, Medjool Village relied on just 10 broad quality grades, limiting how precisely they could match product to market. Today, with 21 refined grades and multiple packaging formats, the company can respond quickly to changing customer demands. From high-end retail specs to large wholesale orders, every shipment now hits the mark with precision, consistency and speed.

Future

Looking ahead, Medjool Village is focused on expanding its global reach and continuing to raise the bar in quality and innovation. While demand from existing customers already exceeds supply, the company is actively working on new expansion projects to increase capacity over the next three to four years. The goal is to double output, which will unlock the ability to enter additional international markets.

At the same time, the company aims to further refine its product range through advanced technologies and drive more sustainable practices across farming, sorting and export. By combining world class cultivation with precision automation, Medjool Village is not only meeting today’s expectations but actively shaping the future of premium Medjool date production.

.png)