Watch all experiences of Ulrich in this video:

One of Germany’s largest apple producers

With 350 growers and 10,000 hectares of orchards, Elbe Obst produces around 150,000 tons of apples each year. Making it one of the largest apple producers in Germany. The company cultivates plenty, nearly 100 different apple varieties, both conventionally and organically. While apples are their main focus, Elbe Obst also handles other fruits such as cherries, pears, and berries. Based near Hamburg, they supply a diverse mix of markets. From premium retailers and discount chains to wholesalers, supermarkets, and export partners.

Meeting the demands of a modern packinghouse

How do you build a flexible packinghouse that handles large volumes, ensures consistent quality, and serves a wide range of markets? Elbe Obst invested in AI grading technology to improve both speed and consistency in their apple grading process.

Over the past few years, Elbe Obst has faced the following challenges:

- Tight delivery windows: Large orders from retailers often require fast turnaround, making capacity and throughput critical.

- Consistent quality: Retailers expect the same level of color, firmness, and defect-free apples, regardless of the time of season or external conditions.

- Subtle defect detection: Defects like pressure marks, blossom-end damage, or stem bowl cracks are difficult to identify with traditional systems.

- Minimizing food waste: Precise removal of defective apples protects the value of good ones — essential for better returns, sustainability and reputation.

- Climate-related risks: Hail, sunburn, and poor color development vary by season and variety but must be sorted accurately.

Every challenge has its solution.

Following are just some of the improvements that Elbe Obst achieved:

✅ Increased throughput due to the faster processing speed of the Elisam-grading machine.

✅ Maximizing value and less food waste through highly accurate sorting results.

✅ More consistent quality with advanced AI defect detection of challenging defects, including the blossom area, stem bowl cracks and pressure marks.

Main goals and challenges in Ulrichs own words

1. Capacity to meet market demands quickly

“Sometimes with capacity, it can be difficult to meet certain demands and get the volumes out on time for customers. Occasionally, there are actions in the market, and then we have to deliver high amounts in a short time. That’s why we need big machines with big capacity. If we can’t handle that, we have to reduce the delivery volume — which isn’t good for the retailers or for us. Sometimes we end up sorting for 12, 15, or even 20 hours a day. And that’s not good for the staff or the machines.”

2. Delivering consistent quality every single day

“Bringing the same quality every day is a key point. We want the same quality. Only better not worse. Today, tomorrow, in ten days, or in two months. Nearly same color, same pressure, same everything.”

3. Difficulty detecting subtle defects

“Some defects are really hard to find. Especially in the blossom area. That’s one of the reasons we switched to the Ellips True-AI version. It’s much better at detecting those hidden defects.”

4. Risk of good apples being downgraded or worse, spoiled

“If we can exactly take out the bad ones, I have no problem with the better ones. But if you have bad apples mixed in with good ones, the whole lot can get infected. On the one hand, you lose money, and on the other hand, you lose your face because you deliver bad quality.”

5. Climate-related defects are becoming more common

“Sometimes hail is a big problem. It’s getting more and more. Growers are thinking about using hail nets. But if you use nets, and then the summer has fewer sun hours, the apples don’t get enough color. Sunburn and cracks also happen depending on the variety. These are normal problems, but we need to sort them out.”

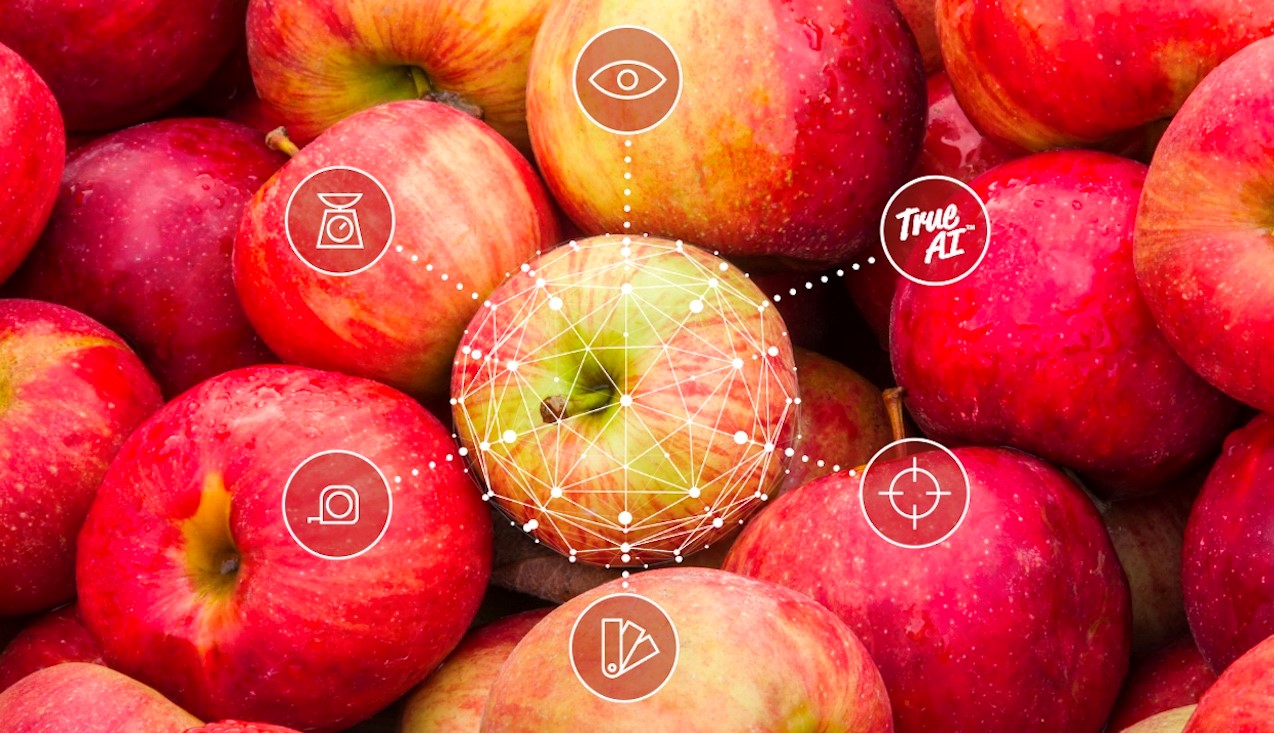

Investing in AI to boost grading performance

To meet rising market demands, especially for fast delivery, consistent quality, and accurate defect detection, Elbe Obst invested in two six-lane Elisam apple graders, combined with Ellips’ latest True-AI technology. This setup increases grading capacity and uses advanced AI to detect subtle internal and external defects that were previously hard to identify.

A fully integrated grading and packing line

With the AI technology from Ellips, the grading machinery from Elisam, and the fully integrated solution from Palm Systems, Elbe Obst has optimized its entire grading and packing line — seamlessly connecting multi-head weighers, palletizers, bin tippers/bin filling systems, washing machines, drying tunnels, packing tables, and automated packaging systems.

From orchard to table: ensuring full traceability

“Elbe Obst takes product quality and food safety seriously. Not just at harvest, but throughout the entire process. From the appearance to the internal condition of every apple, everything is carefully inspected to prevent issues and ensure consistent quality. Grading, packing, labeling, and processing are all handled with precision. As a premium apple brand, Elbe Obst is committed to complete supply chain transparency.”

To guarantee full traceability, they now use SSCC codes generated by Ellips TrueSort. These codes link every package to detailed product data, which is exported to Ellips’ External Statistics Database and integrated into their ERP system. This gives Elbe Obst full transparency and control, from orchard to table.

Choosing the right partner & technology

With 12 sorting machines in total, Elbe Obst regularly evaluates new technology. Typically replacing one machine every two years to keep operations up to date. In 2021, the team was looking for a new machine and took a fresh look at the market. Elisam stood out for offering a compact design, slightly higher grading capacity than competitors, and what looked like a highly functional system. “At first, it was a test,” Ulrich explains. “But the results were super positive — because two years later, we bought the next machine.”

Elbe Obst was already familiar with Ellips technology, having converted the software of two existing apple and pear machines to Ellips systems. Now, with the addition of the Elisam machine — developed in cooperation with Ellips — the setup is fully matched, both in hardware and software.

What were the main motivations for choosing Ellips-Elisam-Palm?

1. Speed and capacity of the Elisam machine

“The Elisam machine brings clear mechanical advantages. Its high-speed operation allows Elbe Obst to run at greater capacity, while the use of small cups ensures gentle apple handling and smooth product flow. The design is also user-friendly and makes cleaning the machine much easier. An added bonus for daily operations.”

2. Powerful defect detection of Ellips True-AI

“Since implementing True-AI technology, Elbe Obst has seen major improvements in both grading speed and accuracy. Subtle defects — especially those around tricky areas like the blossom end — are now detected much more reliably. The system also performs well with pressure marks, which are typically hard to catch with traditional grading software.”

“Operators have noted that the True-AI setup is not only faster, but also really easy to work with. The intuitive interface and smooth product handling make daily operation more efficient. Most importantly, quality sorting is more accurate than ever. A result that’s clearly visible in day-to-day performance. For Elbe Obst, the combination of speed, simplicity, and precision makes True-AI a clear success.”

3. Excellent local service & support from Palm Systems

Elbe Obst and Palm Systems have been working together for several years. When Elbe Obst was searching for a local partner to provide a complete grading solution for both conventional and organic apples, they turned to the proven collaboration between Ellips and Palm Systems. Recognizing the strength of this long-term partnership, Elbe Obst decided to entrust the project to both companies, with Palm Systems acting as the local representative.

“The collaboration with Palm Systems has proven to be both efficient and reliable. As a local partner, Palm plays a key role when service or support even on the grading lines or one of the multiple packing lines of Elbe Obst is needed. Most technical issues are quickly resolved by their nearby team. Often in direct coordination with Ellips when required. Their close proximity ensures fast, effective support, and in many cases, even a quick phone call is enough to get things running smoothly again.”

“Palm understands the practical needs of Elbe Obst’s operation and delivers solutions that fit perfectly. From the dumping and filling sections to the rest of the integration. While minor issues are inevitable in any complex system, the partnership between Elbe Obst, Palm Systems, Ellips and Elisam works well in practice. It's a strong combination that keeps the line running efficiently.”

Results

Following are just some of the improvements that Elbe Obst achieved:

✅ Increased throughput due to the faster processing speed of the Elisam-grading machine.

✅ Maximizing value and less food waste through highly accurate sorting results.

✅ More consistent quality with advanced AI defect detection of challenging defects, including the blossom area, stem bowl cracks and pressure marks.

Increased throughput and faster delivery

“One of the most tangible outcomes for Elbe Obst has been the significant increase in throughput. With the high-speed Elisam graders powered by Ellips’ True-AI, the company can now handle larger volumes of apples in a shorter timeframe — a critical advantage during peak demand periods. Where tight delivery windows once posed a risk to customer satisfaction, Elbe Obst is now able to fulfill high-volume orders without compromising on quality or overloading staff and equipment. This boost in capacity not only ensures timely delivery to retailers but also gives the packinghouse more breathing room in daily operations. The result? A faster, more efficient process that supports both operational flexibility and long-term scalability.”

Raising the bar for sorting quality

“Elbe Obst has achieved a noticeable step up in sorting quality with the Elisam machines equipped with True-AI technology. The apples sorted on these lines consistently meet a higher standard — so much so that buyers sometimes ask whether their produce comes from specific stations like Neuenfelde or Königreich, where the Elisam machines are in use. While the final product in stores may look the same to consumers, internally the team sees a clear difference: more consistent sorting, higher-quality output, and better alignment with premium customer expectations. For Elbe Obst, investing in these machines wasn’t just about speed or capacity — it was about delivering dependable, top-tier results every time.”

Maximizing value and minimizing food waste

“With the precision of AI grading, Elbe Obst is able to channel each apple into the right quality tier — ensuring that every piece of fruit reaches its optimal market destination. Premium apples with ideal color and condition are sorted for the highest-value channels, while lower-grade produce is directed to markets where those specifications are still acceptable. This level of control not only boosts the overall return from the harvest, but also significantly reduces food waste. Defective or rotten apples are accurately removed early in the process, preventing cross-contamination and preserving the integrity of top-quality lots.”

Higher prices and delivering value to the supply chain

“As a result, Elbe Obst can achieve slightly higher prices. Even small improvements, like reducing the percentage of bad apples in the lot from 5% to 1%, make a difference. This benefits everyone involved: retailers get better consistency, customers enjoy higher-quality fruit, and growers see improved returns. And thanks to the flexibility of the system, Elbe Obst can confidently sort for different quality levels without sacrificing speed or accuracy. It’s a solution that delivers value at every level of the supply chain.”

A sweet dream for the future

When Ulrich talks about the future of apple grading, one vision stands out: the ability to sort apples not just by how they look, but by how they taste. His dream? Technology that can detect sugar levels — identifying sweeter apples based on Brix values and channeling them into new quality categories. “That would take quality to a whole new level,” he says. While current systems already excel at spotting internal defects, the ability to grade based on sweetness remains just out of reach. But for Ulrich, it’s a dream worth chasing. A step that could redefine how apples are sorted, marketed, and enjoyed.