In a world where bigger means better, Green Planet Apples proves size isn’t everything. This small, family-run packhouse in New Zealand’s Hawke’s Bay has earned its place by focusing on quality, consistency and reliability. But to maintain that standard at scale and meet market demands, it was clear they needed to raise the bar.

In 2020, Green Planet invested in an Elisam apple grader with Ellips TrueSort to boost throughput, reduce labor, and ensure consistent quality. All while handling fruit with care.

In 2024, they upgraded to Ellips True-AI grading technology to better detect challenging defects, reduce manual labor even further and stay competitive in a fast-moving market. The result: higher accuracy even in tough seasons and more consistent grading across all classes.

Facing growing pressure from larger competitors and losing fruit value during defect-heavy seasons, Sandy Masterson made a clear call to his father:

“We need AI or we risk falling behind.”

That decision marked a major shift in speed, accuracy and reliability. With fewer labor demands and a cleaner, more valuable pack, Green Planet Apples now delivers exactly what growers need to maximise returns and what buyers expect to protect their brand.

How a small packhouse tackled big challenges

Like many smaller packhouses, Green Planet Apples faced increasing pressure to meet rising quality expectations, manage seasonal defect peaks, and keep up with evolving export demands. While their grading system with traditional vision software had already been a strong step forward, it became clear that a new level of speed and precision was needed. Especially during peak volumes and defect-heavy seasons.

In recent years, Green Planet Apples has faced the following challenges:

- Detecting subtle or complex defects at high speed, especially in heavy-defect seasons with issues like stem splits, russet and bruising.

- The risk of reworks or customer complaints due to missed defects in exported packs.

- Lost value for growers, particularly when good fruit was misgraded or couldn’t be segmented effectively.

- Labor shortages and rising wage costs, making efficiency and automation more critical than ever.

- Tight delivery windows and seasonal deadlines, requiring faster throughput without compromising on quality.

Every challenge had a clear impact. And for every challenge they got a solution.

The 3 most important results and benefits

After implementing Ellips True-AI and upgrading their existing Elisam grader, Green Planet Apples saw clear, measurable improvements. Not just in operations, but in the confidence of their growers and buyers.

✅ Faster, more accurate defect detection

True-AI significantly improved the identification and sorting of stem splits, russet and bruising. This led to cleaner packs and far fewer complaints. Even in difficult seasons, the system helps maintain high quality and consistency at full speed.

✅ Major labor savings

Manual grading teams were reduced from up to eight people to just one operator. This freed up labor, lowered costs and eliminated the need for night shifts thanks to the increased speed and throughput of the automated system.

✅ Better returns and more trust

With higher grading accuracy and more consistent quality, growers see better returns on their fruit. Buyers can rely on packs that meet expectations, which helps protect their brand and reduces the risk of rejected loads or rework.

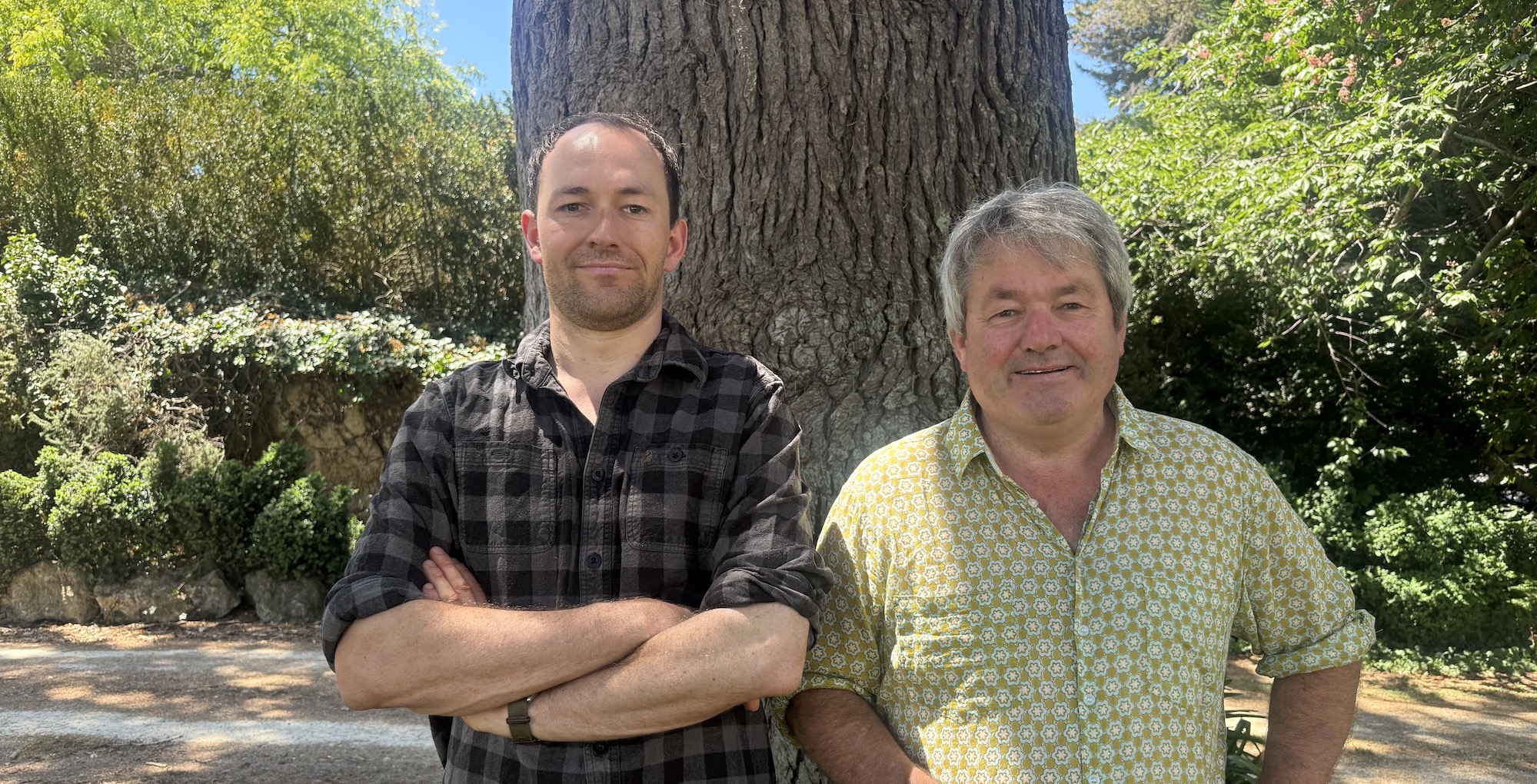

About Green Planet Apples

Green Planet Apples is a small, family-run packhouse based in New Zealand’s Hawke’s Bay. The country’s “fruit bowl”. Founded in 2000 by Harry Masterson and his brother Tom. Now run together with Harry’s son, Sandy. The company has built its reputation on quality, consistency and strong grower relationships.

Harry handles sales and customer relationships, while Sandy runs day-to-day operations. Together they keep the business fast, flexible and personal. Making quick decisions without corporate layers.

The family once ran their own orchards, so they know the realities of growing fruit. That experience helps them empathise with growers and stay focused on what matters most: maximising returns while protecting fruit quality and brand reputation.

Today, as a dedicated contract packer, Green Planet works with 50 to 70 growers and several export companies to deliver perfectly graded apples to markets across Asia, Europe, the Middle East and the US.

Main goals and challenges in Sandy’s own words

With growing volumes and tighter export demands, Green Planet faced increasing pressure on quality, throughput and labor. Before 2020, all grading was manual. Just people, a mechanical grader, and eyes on apples.

It worked for a while, but rising labor costs, inconsistent quality and tight shipping deadlines exposed its limits. So, in 2020, they invested in an Elisam grader with Ellips TrueSort. A major upgrade in throughput, consistency and efficiency

But the industry didn’t stand still. Defect pressure increased. Buyer expectations became stricter. And AI grading was quickly becoming the new standard. In 2024, Green Planet upgraded to Ellips True-AI. Gaining the precision and consistency to stay ahead.

Here are the five key challenges that shaped both investment decisions, according to Green Planet:

1. Inconsistent grading and quality risks

Before 2020

Manual grading was not fast enough and inconsistent. Only part of each apple was inspected, and human error was inevitable. Missed defects meant reworks, complaints or lost value. The main challenge is getting the bad ones out. You can tell people to focus, but some irregularities and defects always slip through.

By 2024

TrueSort improved grading, but subtle defects, especially stem splits, still slipped through. The traditional vision system reached its limits and lacked the consistency to spot hidden or small issues, leading to downgraded good fruit or defective exports. Someone always paid the price: grower, buyer or packhouse.

2. Labor intensity and rising wage costs

Before 2020

Maintaining quality required large manual teams. During seasons with higher defect pressure, more staff had to be added just to maintain standards. If you've got a real problem with defects, you need to put more labor on that grading side of things. It also meant working overtime and at night. It's just a wage drain.

By 2024

TrueSort reduced reliance on manual grading, but during difficult periods up to eight people were still needed on the line. True-AI allowed them to reduce that to just one operator and eliminated the need for night shifts entirely.

3. Throughput pressure and seasonal deadlines

Before 2020

Manual grading couldn’t keep pace during peak periods. Export windows and tariff deadlines made timing critical. In 2019, the team struggled to pack fruit fast enough to meet key cutoffs. Especially in Europe, where tariffs kick in after June and prices drop as global supply increases. Fruit needs to be packed within a certain time frame and on our old technology we just couldn’t get it done. Missing that window meant losing the best returns.

By 2024

Even with TrueSort, high-defect seasons caused slowdowns. True-AI allowed full-speed grading without sacrificing accuracy, helping Green Planet meet key export deadlines and avoid pricing pressure.

4. Lost value for growers

Before 2020

Without reliable grading, fruit was often downgraded to avoid risk. In other cases, defects were missed entirely. Either way, growers lost value on fruit that could have earned more.

By 2023

True-AI enabled more accurate grading and smarter detection. Especially for borderline fruit. Green Planet could now confidently sort into multiple classes, including Class 2, which is still sellable but not suited for premium export. This helped recover value that would have otherwise been lost to waste or unnecessary downgrades.

5. Buyer expectations and market demands

Before 2020

Manual systems struggled to meet retail and export standards, which led to pricing issues or even rejections. Fruit has arrived to market with a defect, and that comes back to us. We’ve had to rework or take a lower price. These things have happened.

By 2024

Even with TrueSort, subtle defects like bruising or stem splits occasionally slipped through. It didn’t happen often, but even a few incidents could damage buyer confidence. As expectations continued to rise, the margin for error kept shrinking.

Choosing the right technology and partner

For Sandy and the team, both investments — in 2020 and 2024 — were based on testing, conversations, and long-term value. They didn’t just focussed on better specs. They needed technology that could adapt, handle volume gently, and consistently deliver results.

Step 1: Finding the right grader (2020)

“When we started looking for a new grader in 2020, it wasn’t a decision to rush. As a smaller, quality-focused packhouse, every investment had to pull its weight. Not just in performance, but in long-term value.”

After speaking with other packers, observing systems in action, and reviewing multiple options, one solution stood out: the Elisam grader. It offered the flow, the speed, and the gentle handling required to protect fruit quality across all varieties. It looked and felt like the right fit for the way Green Planet operates.

Step 2: Upgrading to AI for more precision (2024)

Over time, grading demands intensified. More defects, tighter specs, greater volumes. The traditional vision software provided a solid foundation, but Sandy knew it was hitting its limit.

“It gave us a good base for a few years, but we needed more precision. That’s when we started looking seriously at Ellips True-AI.”

They tested it with their own apples and saw instant impact. True-AI spotted subtle defects like stem splits, russet and bruising more accurately, without slowing the line. It gave them confidence to maintain quality, even under pressure.

“The difference was obvious during trials. It was faster, more accurate, and didn’t disrupt our throughput. Exactly what we needed.”

What were the main motivations for choosing Ellips-Elisam?

When evaluating different technologies, the team wasn’t just searching for faster grading. They needed a system that was robust, adaptable, and simple enough for their team to operate confidently. Here’s why we chose Elisam and Ellips over other systems:

1. Built for high throughput, durability and gentle handling

The Elisam grader combined speed and precision with careful fruit handling. Compared to other systems, it felt more solid, more reliable, and better suited for the real-world demands of a busy packhouse. A machine built for the long run. In six full seasons, the Elisam grader hasn’t had a single minute of downtime. A track record Sandy calls ‘bulletproof.’

2. Software that drives ease of use and operator confidence

From the start, Ellips TrueSort software stood out for being intuitive and easy to work with.

It wasn’t just about defect detection. It was about how quickly our team could get up to speed and run the system independently

We’ve seen other packers struggle with complex setups that demand constant support just to stay operational. And while many packhouses already have graders installed, if your software isn’t easy to use, you’re losing efficiency every single day. Ellips delivers better results with far less effort.

3. Next-level detection with True-AI and easy integration

Upgrading to True-AI took defect detection to the next level, especially for the subtle, complex issues that traditional vision systems often missed like stem splits, russet and bruising.

The difference was clear from day one of testing with our own fruit. Small, hard-to-spot defects that older systems missed were now being picked up with consistency, and without slowing production.

One of the biggest advantages was how easily it integrated into our existing setup. No major changes, no weeks of retraining. Just a smarter, more consistent layer of intelligence added to the system we were already running. It gave us tighter control and full confidence in every box.

Results

Since upgrading to True-AI, Green Planet Apples has seen measurable improvements across their entire operation:

✅ More accurate defect detection for stem splits, russet and bruising

Defects the old system struggled with and missed — like stem splits, bruises and russet — are now caught consistently, even in hard-to-spot areas. Packs are cleaner and more reliable, even during high-pressure seasons.

✅ Faster throughput, even under pressure

Where they once had to slow the line to maintain quality, True-AI allows full-speed grading without compromise. That’s helped the team hit deadlines and avoid production bottlenecks.

✅ Less labor, fewer night shifts

The grading team dropped from up to eight people to just one operator. With higher throughput and fewer slowdowns, night shifts are no longer needed. Plus ease to use software and operating the machine.

✅ More value recovered for growers

Accurate sorting means fruit is no longer downgraded "just to be safe". Green Planet can now confidently segment into Class 2 and other grades, helping growers capture more value from every bin.

✅ Fewer reworks, stronger buyer confidence

Missed defects used to mean reworks or pricing issues. With more consistent pack quality, buyer trust is up and complaints are way down. Giving conficence in every box.