Costa Berries, part of the Costa Group and one of Australia’s largest berry producers, was looking for a way to scale up their packing facilities.

With the harvest volumes beginning to outpace the packhouse, reduced labour availability and rising export demand for premium fruit, the team was looking for a new solution for their packing requirements.

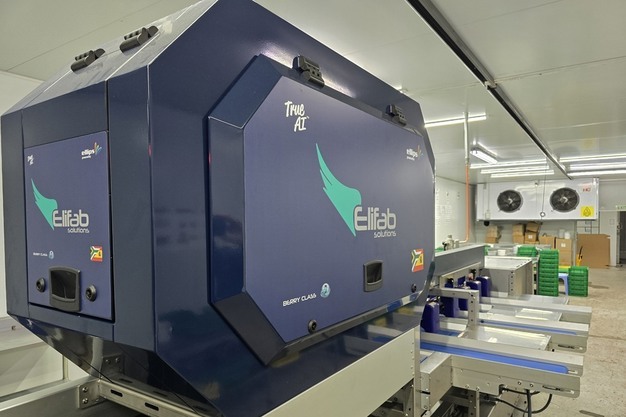

Instead of expanding infrastructure or growing the workforce , Costa invested in a 12-lane Elifab blueberry grader powered by Ellips True-AI grading technology.

The result? A smarter, leaner operation that delivers consistent, export-grade quality — all in a single shift.

The solution has provided full control over throughput, quality, and efficiency — with room to grow, without expanding the shed.

Following are just some of the improvements that Costa Berries achieved:

✅ Increased packing speed — exceeded previous throughputs per hour with an expectation to more than double previous capabilities, allowing the business to handle more volume.

✅ Greater sorting precision — better handling and grading capabilities of soft fruit, bloom retention, and pests like mealy bugs, resulting in fewer rejections and a consistent good quality product for consumers.

✅ Labour optimisation — by packing more fruit within a single shift, Costa has reduced labour pressure in a remote area with limited availability.

About Costa Berries

Part of a larger produce powerhouse

Costa Berries is a key business category within the Costa Group — a diversified global produce business operating across multiple categories. With over 35 years of experience in blueberries, Costa focuses on four core berry types: blueberries, strawberries, raspberries, and blackberries. Across four farms, Costa currently manages 420 hectares of planted blueberries.

Multiple brands for multiple markets

Costa’s operations are built to support year-round supply to both domestic and global markets. They are a leading supplier to Australia’s major retailers — including Woolworths, Coles, and ALDI — and also serve wholesalers and export markets. Export is a growing market with a high demand for premium produce.

Innovation through proprietary genetics

Blueberries are a key produce line within the Costa portfolio. The company has developed several proprietary varieties and is the holder of the Guinness World Record for the world’s largest commercially grown blueberry (20.4 grams). Costa’s globally recognised blueberry Variety Improvement Program develops varieties highly regarded and recognised for their agronomic performance, flavour, size, texture and exceptional eating quality. Jumbo-sized berries (22+ mm) are especially sought after in export markets for their visual appeal and quality perception.

Key challenges driving change

Costa Berries was entering a period of rapid growth. The team had secured additional land, planted new blueberry acreage, and production was ramping up fast. But the existing infrastructure couldn’t keep up — fruit was going to arrive faster than it could be packed.

1. Too much labour, too few people

Labour availability and rising costs is an ongoing challenge across the horticulture industry.

Using existing equipment, the fruit would need to have been packed in double shifts, and export fruit would have to continue being packed by hand in the field.

2. Export markets demand more — and rejections hurt

Top-tier customers — especially in Asia — expect blueberries with intact bloom, firmness, and no visible pest damage. Meeting these high standards — consistently and at scale — is critical.

Greater control, consistency, and visibility across every punnet — without compromise, ensures the full value of the harvest can be realised

3. The shed couldn’t grow — but the business had to

Costa didn’t want to expand the shed or add a second grader. Instead, the team needed to grow without expanding infrastructure or adding operational complexity. A single high-throughput grader that could handle the job — right within the current footprint — was the ideal solution.

The Costa Berries team faced a strategic decision:

Expand the shed and invest in more conventional equipment or invest in high-throughput technology that could scale within the same footprint.

They chose the latter — a smarter, more efficient solution that supported their long-term growth strategy without overloading their infrastructure or workforce.

Choosing the right partner & technology

Costa Berries first connected with Elifab-Ellips at Fruit Logistica 2023 in Berlin, where a live demo sparked serious interest. From there, they launched a thorough, independent investigation—visiting different packhouses, speaking directly with existing users, and comparing several vendors. Despite Elifab’s higher price point, Costa looked beyond the initial investment. What truly mattered was the return on investment: higher throughput, labour savings through single-shift operations, fewer product rejections, and a compact design that avoided costly shed expansions. Together with the Elifab-Ellips team, they developed a detailed business case and packhouse layout built for long-term payback.

What were the main motivations for choosing Ellips-Elifab?

1. High-speed grading with minimal footprint

“Elifab’s high throughput grading line is already transforming the way we work. While our volumes are not yet allowing us to test the full throughput capabilities, we’re well on our way — and the system clearly has the capacity to get us through our most challenging days without breaking a sweat. It’s given us the confidence that we can finally match field production without needing to expand the shed or run double shifts. That’s a massive win for labour availability and cost-efficiency.”

2. Gentle handling to preserve maximum value

“Despite the high speed, product handling remains gentle. The system is thoughtfully designed — reduced drops, fewer transitions, and better control over how fruit is presented to the cameras. From a mechanical perspective, it’s clean, sturdy, and well-engineered for efficiency and scale.”

“Preserving bloom was critical for export quality, especially in markets like Hong Kong. The AI cameras, combined with smart handling, help us maintain premium presentation. The interface is intuitive, and settings are easy to verify. Overall, it allows us to sort better, waste less, and export more.”

3. Smart sorting powered by Ellips True-AI

“One of the biggest drivers for choosing the Elifab with the Ellips vision system, was its ability to sort more accurately — and more intelligently. Traditional systems struggled with detecting subtle but critical defects — like soft fruit, dehydration, pest damage, bloom, cracks, stem tears, and early-stage mold. The Ellips True-AI system not only picks these up with precision, but also reliably identifies stem and calyx — essential for delivering a uniform, high-grade product every time.

4. Real-time fine-tuning with instant verification

“One of the standout features of the Ellips-Elifab system is the ability to test new settings live — without disrupting the full line. Thanks to dedicated test exits, operators can adjust sorting parameters and immediately observe the impact on a sample batch. We can tweak a setting, see the result in real time on the test exit, and only push it across the full line once we’re happy. That level of control is something we’ve never had before — and it makes the AI usable in a practical way.

This test-before-you-scale approach gives the team the confidence to fine-tune performance and verify that the machine is doing what they expect. In short: it gives the team fast feedback, maximum control, and peace of mind — with direct impact on quality, efficiency, and profitability.”

5. Cleaner product flow = fewer rejections and healthier punnets

One of the most overlooked — but critical — benefits is the system’s ability to keep compromised fruit out of the premium product stream. Even a small number of damaged or leaking berries can contaminate an entire punnet, leading to higher risk of disease, mold, and customer complaints.

By consistently removing those weaker berries before they make it into final packs, the Elifab-Ellips setup helps Costa reduce the risk of infection, extend shelf life, and cut down on rejections — especially in premium export markets where expectations are very high, and tolerance is very low. The result? Cleaner punnets, more confidence, and stronger brand protection.

Confident onboarding and hands-on support

“Installation and training were seamless. The Ellips-Elifab team stayed on-site for weeks to ensure everything ran smoothly and that Costa’s staff were fully up to speed. They didn’t just deliver a machine — they made sure the team felt confident operating and maintaining it independently. That peace of mind made a big difference, especially when introducing new technology at scale.”

Results

Following are just some of the improvements Costa Berries has experienced:

✅ Increased packing speed — exceeded historical demonstrated best performance and anticipating to reach up to 4 tonnes per hour, allowing the business to handle more volume than ever.

✅ Greater sorting precision — including better detection of soft fruit, bloom, and pests like mealy bugs, resulting in fewer rejections and better export quality.

✅ Labour optimization — by packing more fruit within a single shift, Costa has reduced labour pressure in a remote area with limited availability.

Boosting capacity without expanding the shed

“The Elifab system helped us solve a major bottleneck. Our throughput has increased, all within the same footprint. It means no costly shed expansion, no double shifts, and future growth potential.”.

Higher quality, fewer rejections, more export confidence

“Preserving bloom was critical for our export markets — especially Hong Kong. With the Elifab grader, bloom loss has been significantly reduced. We’ve also seen better rejection control on soft fruit and pest-affected berries. That helps us protect quality, prevent waste, and move more volume into premium channels.”

Enabling future cost savings

“It's still early, but we already see efficiency gains. Our goal is to eventually replace high-cost field packing of export products with line packing — something we can now consider because the difference in punnet quality is noticeable. That could reduce costs significantly over time.”

A shared success across the Costa Group

The success of the Ellips-Elifab solution didn’t stop at Costa Berries. It sparked momentum across the broader Costa Group. After seeing the business case, results, and hands-on experience in Australia, Costa’s international berry division shared those insights with African Blue — their joint venture partner in Morocco.

The outcome? African Blue decided to invest in a Elifab grader with Mat Exakta punnet fillers, that have now been installed to support their own growing operations.

This cross-border collaboration shows the strength of the Costa network: when one region finds a smarter way forward, others follow. It's not just a single success — it’s a group-wide shift toward higher quality, greater efficiency, and shared innovation.